Lifecycle support for Hanas New Energy LNG Plant

Hanas New Energy LNG Plant

China’s Hanas New Energy is one of the world’s diverse energy solutions providers. Hanas New Energy’s core business is the provision of wind power, solar-thermal power and distributed energy. The Group also delivers production of LNG (Liquefied Natural Gas), CCHP (Combined Cooling, Heating and Power), urban gas operation, and centralized natural gas heating and cooling. Hanas New Energy is promoting China’s energy transformation.

Hanas New Energy owns and operates the largest LNG Plant in China with a production capacity of nearly 1 million tons per year. The plant liquefies natural gas from the CNPC West-East pipeline, using the APCI liquefaction process with a single mixed refrigerant (SMR) in two parallel liquefaction trains. LNG produced is stored in a 50,000 m3 tank and exported by trucks from the terminal.

Implementing the CMMS before plant start-up

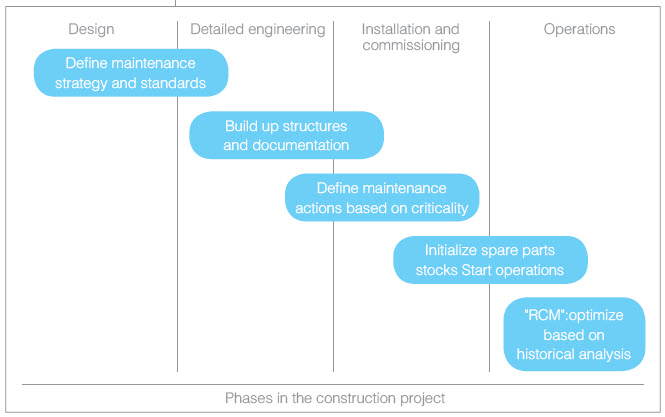

In line with international best practices, a Computerized Maintenance Management System (CMMS) was implemented during the construction of the plant (2009-2011). Siveco has over the years refined this practice to meet the demands of Chinese projects, where as-built documentation is difficult to obtain and operators lack experience of modern maintenance practices. Hanas New Energy consequently selected Siveco and its “Coswin” CMMS.

Siveco maintenance specialists worked alongside the EPC and Hanas New Energy engineering team until plant start-up in early 2012, thus ensuring smooth transfer of technical documentation from construction to operation, supporting plant start-up with an accurate technical database and enforcing good maintenance practice from day one.

Efficient work management

Once the LNG plant was put in operation, the CMMS served as the single repository for all maintenance, inspection and testing information. Work planning is done in Coswin, ensuring greater work efficiency and control over the most important aspects of the process.

Coswin 8i in Hanas LNG plant

Plant visit by the governor of Ningxia Hui Autonomous Region

According to Plant Manager Dietrich Roeben:

“The CMMS ensures most efficient work turnaround for all preventive and corrective maintenance, inspection, testing and plant modifications. The CMMS also plays a role in effective risk management, which is crucial to our operation, aiming at zero harm to people and environment, surpassing regulatory requirements.”

Continuous improvement

Years later, the Siveco team continues to support Hanas New Energy LNG Plant with regular training and coaching, as well as support. Coswin stock management module was also put into use in March 2016. In 2018, the system was upgraded to the latest Coswin 8i version and the Purchasing module was also implemented.

In the word of the Plant Manager: “In spite of inevitable personnel changes since the plant started, the CMMS and support from Siveco has remained strong, ensuring true lifecycle support and continuous improvement for our plant.”