Q&A on optimizing operations in tough economic times

Introduction

Siveco China’s GM presented the keynote speech at the 10th Annual Process Industry Engineering & Maintenance Congress in Shanghai (September 2013) on the topic of “Optimizing operations in tough economic times – Experience with Chinese plants”.

The speech expanded on an article we published on how to financially justify a maintenance project, by providing many real-life examples and practical advices. Interested reader will refer to this article or contact us for a copy of the presentation slides (email us at info@sivecochina.com).

This month’s Reliability article will summarize two of the presentation’s key points, which were not covered in the original article. It will also answer some of the most frequent questions that were asked during the event.

The difference of perception between technical managers and top managers

The presentation explained the difficulties technical managers, especially in China, face when trying to launch improvement project. The result is technical managers very seldom initiate improvement project, which are usually top-down decisions by the CEO.

One aspect of the problem is that technical managers and top managers tend to have very different perceptions of ROI calculations and other savings estimates. It is not uncommon for maintenance managers to think such figures make no sense whatsoever: they are just wild guesses and lack credibility. Top managers often have the opposite reaction to the exact same estimates; they think they provide great justification for projects.

The presentation provided several vivid examples of such situations, where technical managers refused to discuss the matter further, while their plant managers, GM, division managers, sometimes board of directors, took actions based on the same ROI report. Years later, it is not uncommon to find top managers got promoted further up in the organization, while the maintenance managers remain in the same position.

This difference is also visible in the results of the 2012-2013 Maintenance in China survey, which shows major discrepancies between technical and management-level respondents from the same company. While technical managers often consider their plant is running well enough, top managers see much more potential for improvement.

Based on our experience at Siveco, we recommend that technical managers first of all recognize these differences and then use them to get things done and to advance their careers! Whether you like it or not, you can use ROI figures to get your projects approved and to grow your responsibility within the company!

The growing importance of maintenance in a slowing economy

With the Chinese economy slowing down, costs rising and regulatory controls increasing in China, many companies will also slow down investments and perhaps even launch cost-cutting programs, making decisions even harder: how do you go to your boss asking for money, when the entire company is talking about reducing cost?

As shown by many Siveco audits, but also more generally by the latest Maintenance in China survey, maintenance is rarely optimized in China, as it has seldom been the priority. This means there is usually good ROI potential from maintenance projects, which is excellent news when companies need to find new ways to reduce losses. For example the survey shows that for 55% of respondents, preventive maintenance represents less than 1/4th of the maintenance activity, which is abysmally low. 70% of respondents (mostly top managers) say they will pay more attention to maintenance.

This is also good news for maintenance professionals, who see their role in the company gaining more importance, as their employer starts to recognize maintenance as a source of profit. This phenomenon has been observed in western economies before and, from the standpoint of a maintenance service supplier, we know that for us business usually gets better during times of economic crisis…

Questions and answers

Q: It is very hard for us to calculate ROI as we do not have all the data and I feel they are just guesses, not suitable with our company culture (German). At the same time, we know we need external help. Can you start with a free service to prove the value of your service?

A: Our experience with German companies is, on the contrary, that they respond very well to our approach, with an initial maintenance audit (usually a service package for which customers are willing to pay) and presentation of our findings, with recommendations and associated ROI estimates, to the top management. Most of our projects with German customers have actually started that way.

Our practical recommendation is that (1) you inform your top manager that you think you need external help with maintenance and that you met us; do not try to justify the project at this stage and (2) we make direct contact with your GM, explaining we met you and you expressed this need; we propose a short meeting to discuss his views and expectations of maintenance performance. After that meeting, we will see what can be done. In the worst case, we all learn something in the process, at the expense of only a few hours work.

Q: Siveco’s approach to use benchmarks based on international standards seem very interesting. Can you give us a copy of those standards?

A: During the conference, we presented various benchmarks, with a focus on two key metrics from the standard EN 15341 Maintenance – Maintenance Key Performance Indicators and related benchmarks. Relatively easy to compute and to present in a simple graphical format, those indicators provide a strong indication of a company’s ability to fund its maintenance. We systematically calculate those before going into further details of the company’s performance and organization.

Having said that, we cannot simply give you copies of the standards, for two main reasons. First of all, those standards are copyrighted and rather expensive to purchase! Second, perhaps more important, you cannot simply read them and apply them right away. International standards are not always easy to read and require experience for their application, for example to calculate the metrics in the right way, and to interpret the results. In addition, benchmarks (by industrial sector and type of plant/process) are not part of the standards and should be obtained separately, while a company like yours only need those information relevant to your own industry sector or plant-type. Our recommendation is to involve Siveco in this process, first in the form of a detailed discussion on site (during which we can explain those metrics in more details and even try to estimate your figures).

Q: We know your company for many years already, but we use another CMMS (SAP PM), so unfortunately we cannot work with you, which is a pity!

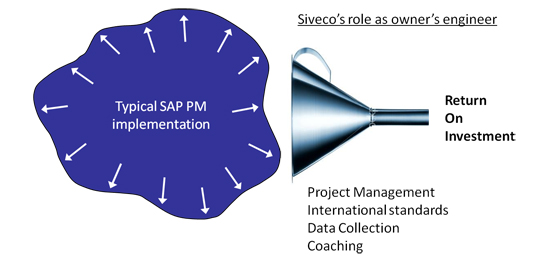

A: Customers are sometimes confused by our dual business: software and engineering. For one thing, our official Chinese name has “software” in it – because you can’t have both software and engineering, so you have to make a choice, and the choice we made provides very significant tax benefits! Maintenance engineering services are however part of our business scope, by far the largest part in terms of revenue. Many of our projects involve a CMMS software we did not supply, for example IBM, INFOR or SAP products.

We have extensive experience providing maintenance consulting services related to SAP PM, with two main axes: (1) data preparation services for new SAP PM projects (i.e. we build up the plant functional and equipment structures, as well as all related data) and (2) audit/optimization of existing SAP PM systems. For new SAP implementation, we can also act as “owner’s engineer” to help design the blueprint, with specific “maintenance management in China” expertise that IT consulting firms do not have.

For more information on our services related to SAP PM, please see “Getting the most out of SAP PM” or contact us.

Q: The ongoing SAP PM implementation is managed by our corporate IT, with very senior consultants, and two external consulting firms (one in charge of blueprint, the other in charge of configuration). They let us collect data from PIDs, which of course we cannot do, but a lot of things (coding, structure) nobody is very clear about. We would need external help, but we do not have a budget for this. Maybe your company should talk to SAP consulting firms?

A:There is a real gap in the Chinese market between IT consultants, who only manage SAP projects from the IT and “top management” point of view (with business expertise in finance and supply chain, but never in maintenance) and customers, who lack the experience using such systems for maintenance improvement. The example you raised is typical: the consulting company provides Excel templates and expects the customer team to fill them up. Customers however do not have the full understanding of how this will impact their future usage of the system, its reporting and analysis capability, and how it will support their maintenance strategy. The result is perhaps acceptable from an IT perspective (as long as the data can be uploaded in SAP) but created huge operational problems down the line. Most SAP PM systems (and other CMMS) that we audit are severely underutilized for this reason and contain a lot of garbage data. Most often than not, maintenance teams get blamed for this: “your team was not mature enough”!

More and more companies realize this gap, both plant owners like you, as well as some consulting firms, who have suffered from such problems. Budgets are however controlled by the plant owners, who should either budget for a separate engineering assistance contract with Siveco or formally instruct their consulting firms of their need. Failing this, there is no way we can get your consulting firm to pay us! Our experience is it easier for the plant owner to sign directly with us a separate maintenance engineering contract, a relatively small budget compared to the huge SAP project. We found that corporate IT departments usually consider this is a “customer” problem i.e. the plant should arrange the necessary resources to populate the SAP database, either in-house or via a third-party contract: the budget will not come from IT.

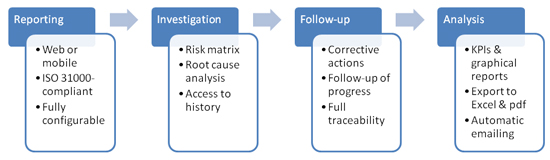

Q: You demonstrated your HSE solution at the booth, with mobile phones, tablets and touch-screen, which was very impressive but perhaps too advanced for our company right now, we are looking for a simpler website where we can register and track problems.

A:We indeed tried to put on a show and attract people to our booth with the huge touch-screen… And mobiles have become so prevalent today: we believe that technologies used in the industry should be at least as advanced as what we all use in our daily lives… Having said that, the core of our HSE Incident Reporting system is a simple website that even small customers can use on a SaaS basis (monthly subscription, no IT installation whatsoever you just browse to a website and use the system). The system can be accessed on any browser, from any device. Everything else you saw at our booth is extra, which probably you do not need: only our largest clients use touch-screens in a central national control room.

Our September newsletter has an overview of the HSE Indicent Reporting system on page 7. Feel free to contact us for more details. The system is particularly well-suited for multisite operations, although it could also be used of course for a single plant (but in this case the need for a centralized web-based solution is debatable).

Q: We are a local state-owned company, we don’t care about ROI, only projects that make our company look good and for which we have a budget.

A:Our experience with state-owned company is not exactly that, although we understand where you come from. In fact, the difference of perception between technical managers and top managers (note: described during the presentation and in this article) is probably ever more acute in local companies. State-owned companies do care about performance improvements, reducing losses, improving safety, meeting the State’s strategic goals, etc. They also care about the long-term value of the investments in plant assets, perhaps even more so than multinationals that are focused on their stock price and the next quarterly results. State-owned companies also tend to have a much lower staff turnover, which means that improving the skills of their personnel becomes even more strategic. Finally, they are usually very large corporations with many assets.

All this makes maintenance improvement more relevant, not less, to SOEs … The need to have a budget is rather similar in MNCs, but our experience is that state-owned firms can be more flexible in using up excess budget (if any) before the end of the year, which is often an excellent way to get a project started!

Our recommendation would be to arrange a discussion on your possible needs and to see, if a project makes sense, how it could match your budgetary constraints. Some of our best customers are Chinese SOEs and have enjoyed excellent results. Products include Changcheng Property Group, Fushun Mining, Sichuan Lutianhua.