Taiwanese waste-to-energy plant optimizes its entire operation with Coswin

SITA Waste Services Limited, Taiwan Branch, Renwu Plant

SITA Waste Services Limited (www.sita.hk) is a subsidiary of SUEZ ENVIRONNEMENT. With 80,000 employees and a worldwide presence, SUEZ ENVIRONNEMENT is a world leader exclusively dedicated to water and waste management services. From waste collection to recovery, SITA covers the entire waste cycle. SITA is offering a wide range of recognised expertise in the waste management industry.

SITA was awarded a contract in Taiwan by Kaohsiung government for the operation and maintenance of Renwu Incineration Plant under a 20 years contract. Commencing from December, 1st 2000, the facility is managed by high calibre crew trained by SITA for the purpose of maximizing energy efficiency, and meeting the most stringent environmental protection standards in the world.

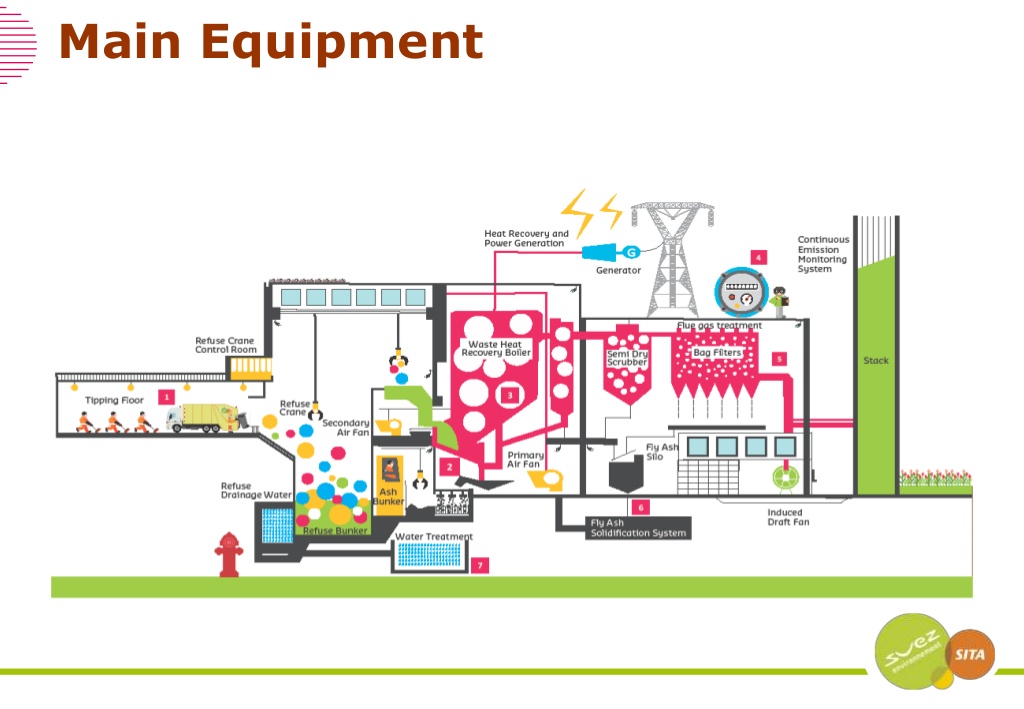

The facility is designed to incinerate 1,350 tonnes each day of blended non-hazardous combustible solid waste with a weighted-average heating value of 2,300 kcal/kg. The energy generated is converted to a total of 33 MW of electricity.

Main equipment at SITA Renwu Waste Incinerator

SITA Waste Services Limited, Taiwan Branch, Renwu Plant

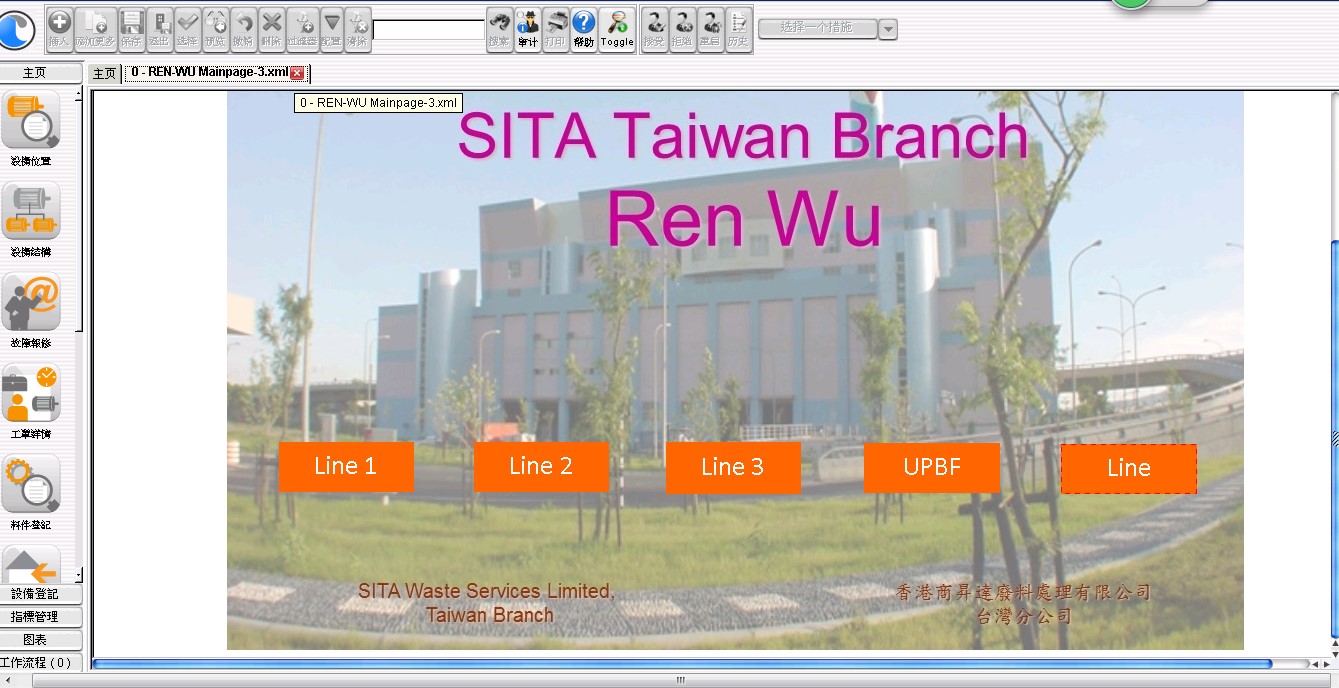

In December 2012, SITA Waste Services selected Siveco China to implement a Computerized Maintenance Management System for the Renwu waste incinerator. The choice of Siveco was based on the company’ successful experience at another SITA facility located in mainland China: SITA, in joint venture with the Shanghai Chemical Industry Park (SCIP), has designed, built and operates a 60,000t/year hazardous waste incineration plant near Shanghai (read the SCIP SITA case study here). Siveco Group also has extensive experience of waste incineration plants worldwide.

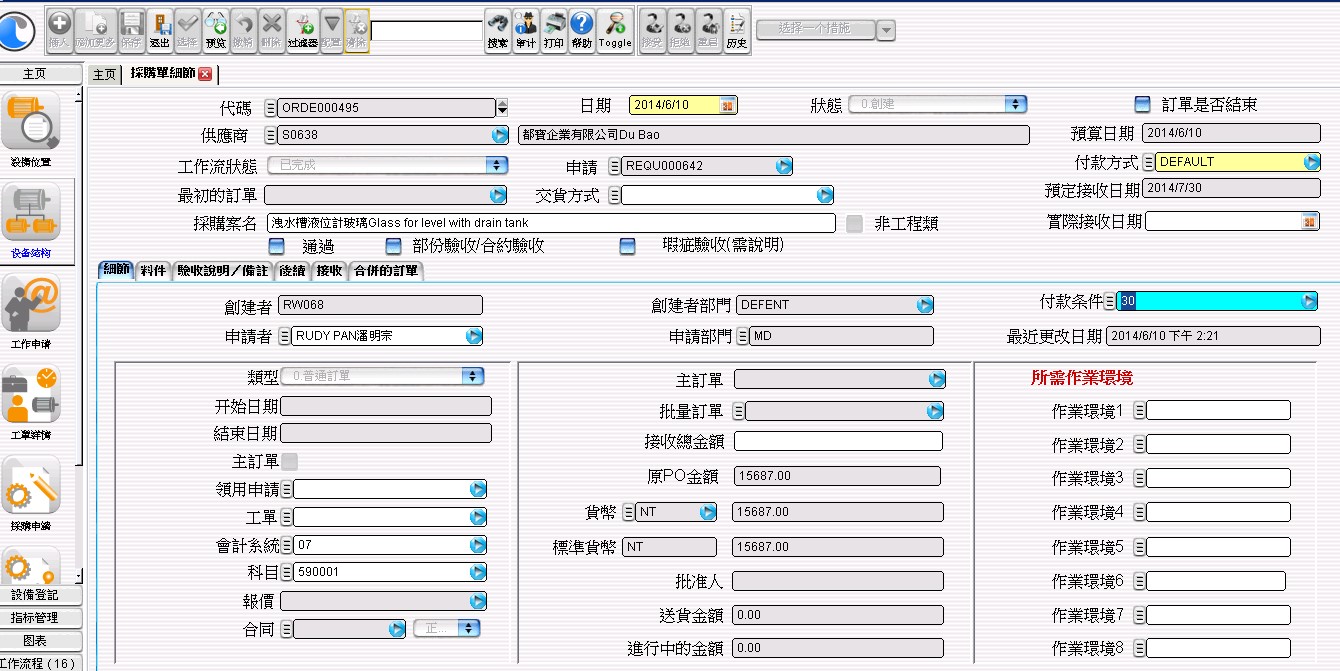

The project covered the implementation of the Coswin CMMS, with a step-by-step approach aimed at promoting maintenance improvement at the plant, through a progressive structuring of the maintenance activity towards systematic analysis and preventive maintenance.

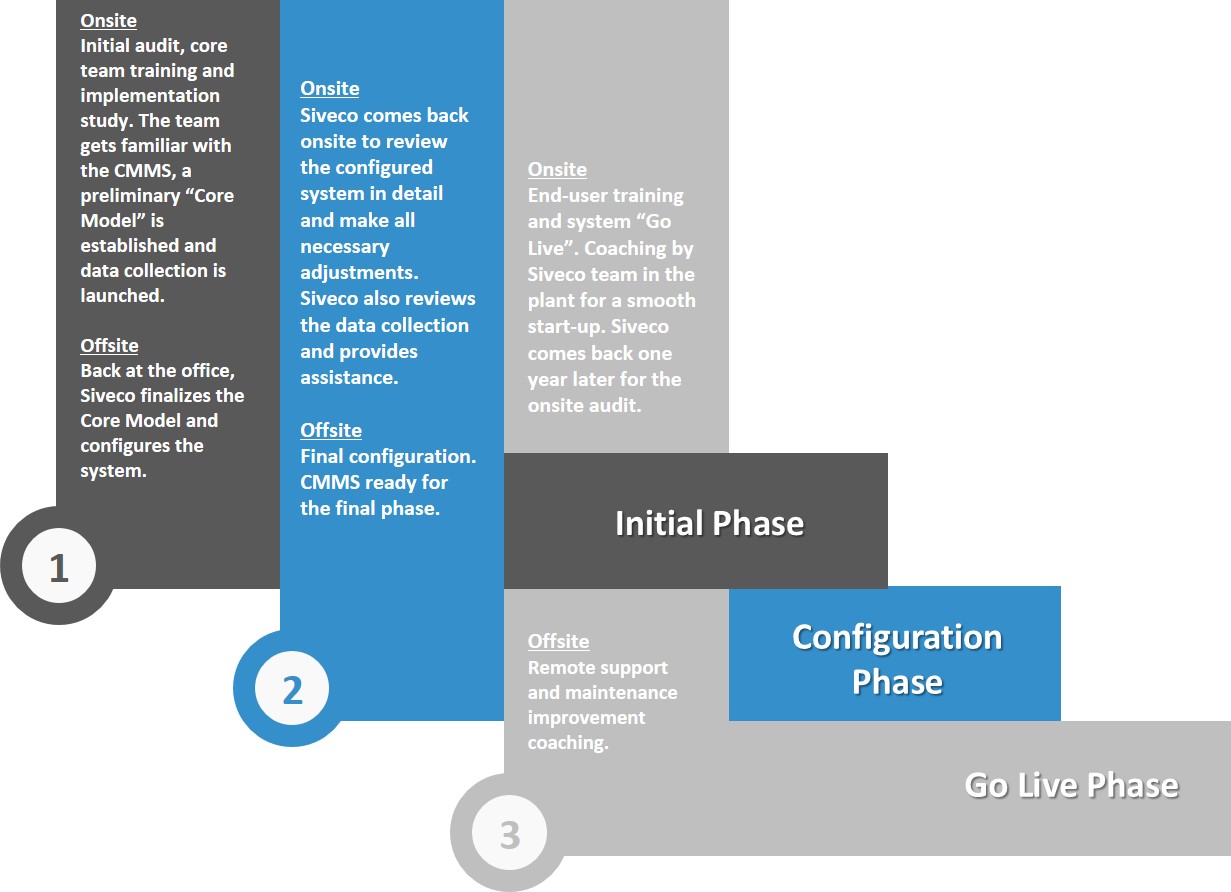

The project was entirely managed by the Siveco China team, traveling onsite to Kaohsiung, with support from the Siveco back-office in Shanghai, following the company’s well-established “export” implementation model for CMMS.

The Siveco implementation methodology builds on over 20 years of implementing maintenance solutions in utility plants all over the world, either for existing plants or as part of new construction projects, and specific experience accumulated in recent years by the China team. Siveco has developed a cost-effective and proven model whereby Siveco engineers set up the main system in China before delivering it onsite.

Siveco engineers will come to site at the initial, middle and final stages of the project, ensuring a smooth CMMS implementation. This approach, used for the SITA Renwu project, is summarized below:

The CMMS project started in January 2013. The new management system was in place eight months later, in September 2013, after which the project entered its Enhanced Maintenance Support phase, during which Siveco monitors system usage on a monthly basis and comes back onsite once a year (see here for more on Siveco’s Enhanced Maintenance Support).

A user-friendly system to support a comprehensive management model

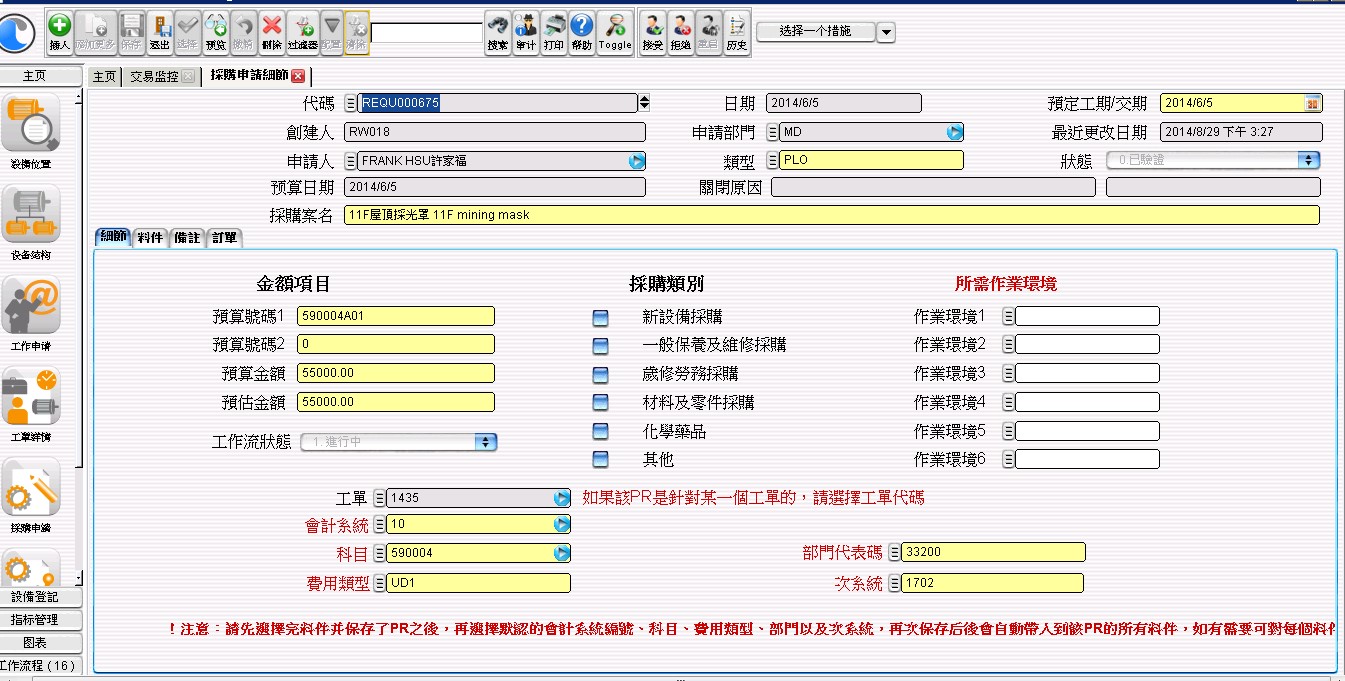

All departments of SITA Renwu have taken part in the project and are now using the system, which covers a comprehensive functional scope: equipment management, work management (corrective maintenance, preventive maintenance and overhaul management), spare parts stock management, purchasing management, reports and analysis. The entire management team was involved under the plant manager, with additional support from China-level management. Several exchange meetings were also organized with other SITA plants using Coswin. As a result, the entire management of the Renwu plant was streamlined and the system will continue to support improvement for years to come.

Another key aspect of the CMMS is the use of Coswin Diagrams to easily navigate the system and graphical management and analysis reports. The reports offer support for management meetings at departmental and plant levels.

As part of the Enhanced Maintenance Support (EMS) contract, Siveco will also analyse the results obtained, the utilization of the system and resulting operational improvement, in order to suggest improvements. The last EMS visit took place in September 2014, during which improvement actions for the coming year were clearly identified by the joint SITA-Siveco team.

“Siveco team had demonstrated their expertise in CMMS development and implementation that bring Ren Wu CMMS project a success. We had raised quite a few special requests during the development phase that may not be common to other industries. Siveco team managed to find solutions to adjust the CMMS to best fit our needs. I am expecting Siveco to be our long term partner that brings our maintenance management to a higher level.” said Mr. Franco Wong, General Manager of SITA Waste Services Limited Taiwan Branch.

“The selection of Siveco as CMMS supplier and as the solution implementer for Renwu WTE plant is part of our long term maintenance strategy in the region. Siveco is able to deliver a friendly and efficient tool and is guiding the local team during implementation. After implementation, Siveco is supporting the local team by a succession of Audits to improve the usage of the system. Siveco is a professional Company offering maintenance solution for the industry. They differentiate themselves with their local team who can speak the maintenance language. The solution implemented has helped us in the analysis of maintenance data and in the orientation of the maintenance strategy.” Francois Jenny, Business Unit Director.

A long term relationship

Based on the results obtained in the SITA Renwu and other projects with Siveco, SITA has strengthened its partnership with Siveco: the CMMS COSWIN and its mobile solution for plant technician, known as bluebee®, will be deployed to all future SITA sites in Asia. Siveco also assists SITA to develop its in-house maintenance management training program.