Strong support for HSE with Coswin 8i

This Tips & Tricks is dedicated to the Health, Safety and Environment (HSE) features of our plant maintenance software Coswin 8i, a key part of our Smart O&M solution. As shown in our latest market studies, Risk Prevention, and more particularly HSE, is a top priority for plants and infrastructures owners.

Most Coswin users have already seen the standard Do’s & Don’ts functionality, which as part of the Work Order (note that this tab may have been hidden in your installation of Coswin, talk to you system administrator if we do not see it) and can provide support for HSE in a simple manner. Do’s and Don’ts are structured instructions that can be printed out with the WO. They can be defined at the Equipment level.

Coswin 8i incorporates many other HSE functionalities. This article will explore some of them.

HSE Dashboard

A dedicated Dashboard – the main user interface to Coswin 8i – can easily be created for HSE users. The dashboard can incorporate dynamically updated KPIs, plant layouts and maps, as well as direct links to all required functionalities.

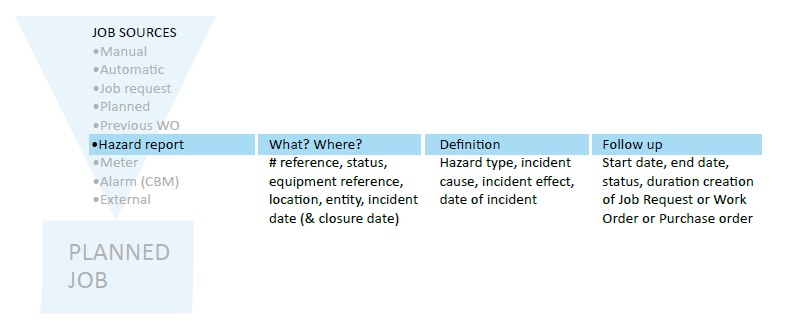

Hazard Report

The Hazard Report is available for managing incidents or events that require attention. Its purpose is to lead to an action plan so that the incident does not repeat.

The Hazard Report can generate various documents or transactions: Job Requests, Work Orders or Purchase Orders.

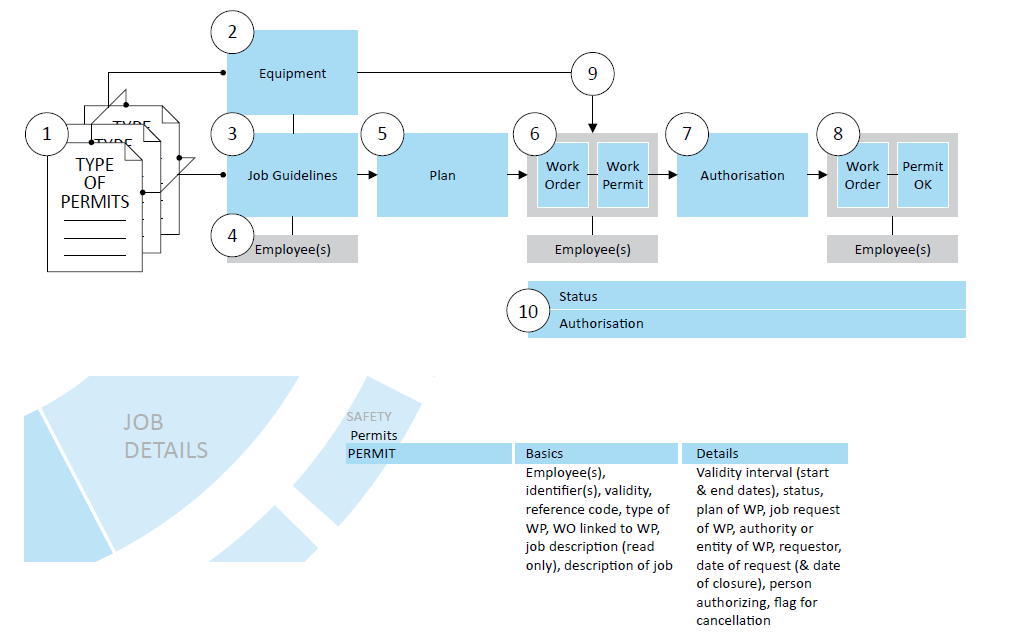

Work Permit

The Work Permit (or WP) module is used to manage Work Permits, that is: raise requests for Work Permits, approve requests for Work Permits (that may be manual, or occur automatically from other Coswin modules, for example Work Orders, Planning) add individuals or employees to Work Permits, and to delete & modify.

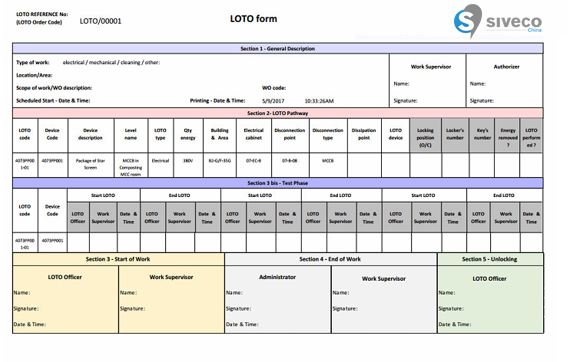

Lockout Tagout (LOTO)

Coswin 8i provides extensive coverage for lockout tagout (LOTO) or isolation procedures. Energy sources and other equipment connections are defined in equipment structures. LOTO pathways indicating LOTO type (locking device) are also pre-defined. Finally, Coswin 8i manages the execution phase, interlocked with the Work Order and Work Permit process: maintenance work cannot start until the isolation has been completed; production cannot restart until the LOTO order has been closed. This can be strictly controlled using QR-coded LOTO orders, to be scanned by production staff.

Personal Protective Equipment (PPE)

Coswin 8i provides a dedicated PPE module to track the usage of Personal Protective Equipment (PPE) by technicians, to manage their condition and lifecycle.

Coswin 8i can manage all types of PPE. For each particular task, the required PPE to be provided to employees can be defined. Coswin 8i tracks all related information (usage of PPE by employees, PPE expiry date, quantity of available PPE, periodic checks etc.) to ensure regulatory compliance. Related reports can be issued directly from Coswin.

Work preparation using embedded BIM models

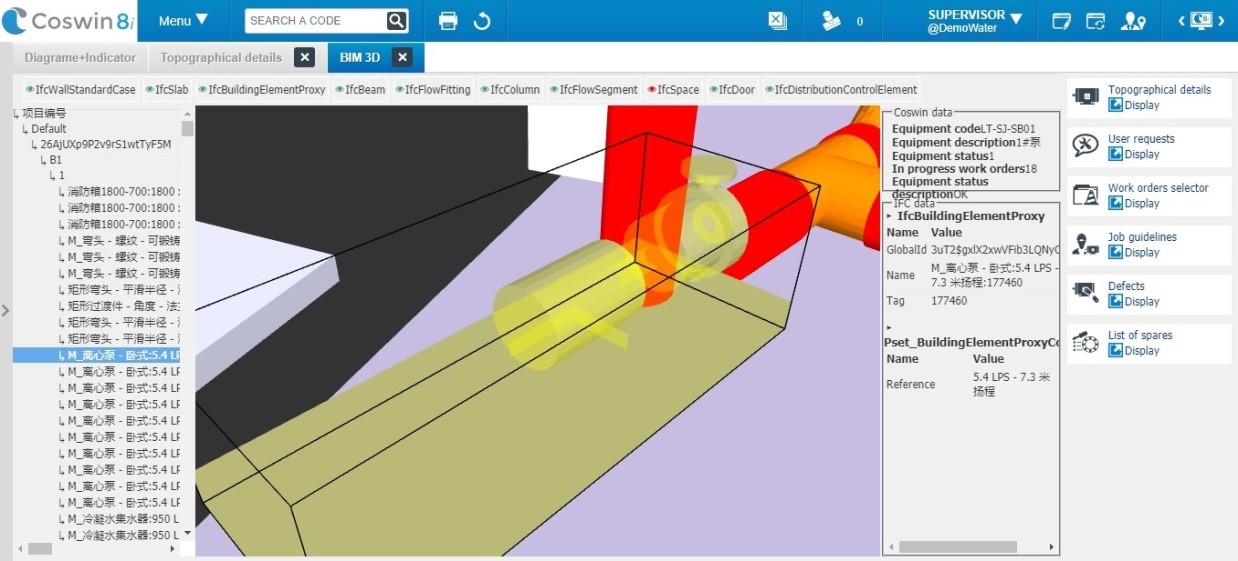

Coswin 8i features a fully integrated BIM viewer based on IFC standard. The viewer allows opening the 3D model directly from relevant Coswin screens.

Allowing users to access all information required for work preparation and HSE, with the corresponding BIM view centered on the target equipment. All related technical information can be accessed with a few clicks. The system can generate a list of disconnections and lock-out points, to be added to the work permit. Similarly, spatial information (access door, piping, distances…) can be studied before execution of the work.

Mobile support for HSE

The bluebee® mobile app supports all onsite activities, syncing all data with Coswin 8i. Non-compliance and risk areas are instantaneously reported. Using WeChat or any other QR code scanning app, users can simply report problems with their phone by scanning the equipment QR code. This easy-to-use solution motivates everyone to report incidents and help prevent disasters. bluebee® can be installed on normal Android phones or tablets or on rugged industrial devices, including explosion-proof ATEX-certified models for use in hazardous environments.

An open system

Coswin 8i features other HSE functionalities not listed in this brief overview. In addition, Coswin provides very powerful customization tools which can be used to add data field related to HSE into existing screens, but also to create entirely new functionalities. For more on this topic, see this previous newsletter article: https://newsletter.bluebeecloud.com/en/tips-tricks/coswin_8i_customization_tools_in_action/.

If you have questions on how Coswin 8i and Siveco could help improve HSE in your facilities, please do not hesitate to contact us at info@sivecochina.com.