Quick benefits from underutilized COSWIN functionalities: Work Permits

This article is the second in a series aimed at familiarizing our readers with lesser-known COSWIN functionalities, which can easily be configured by customers themselves to bring immediate benefits. For the first issue on Contract Management, please see here.

COSWIN includes a powerful Work Permit module that allows users to manage all types of work permits for Health, Safety and Environment (HSE) or other regulatory purposes. Examples include lockout procedures, fire permits, hot work permits, elevated work permits, electrical work permits, access permits, etc. The standard facility can easy be tailored to match local regulations and industry or company-specific requirements.

COSWIN Work Permit

The Work Permit (or WP) module is used to manage Work Permits, that is: raise requests for Work Permits, approve requests for Work Permits (that may be manual, or occur automatically from other Coswin modules, for example Work Orders, Planning …,) add individuals or employees to Work Permits, and to delete & modify.

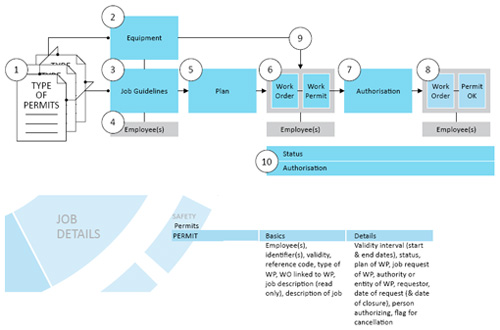

① A library of Work Permits types (WPs) can be created and …② the permit type assigned to an equipment. Restrictions can be applied, for instance, every time there is an unplanned job on equipment XYZ, a permit must be raised ③ or the permit type can be assigned to a job. In this case whenever that job is to be done to whatever equipment, the constraints of the permit apply ④ employees (either internal or external) are likewise assigned to a job, these employees statuses and authorization will be linked to the WP (see below) ⑤ after a plan has been created and work orders created ⑥ the related work order will generate or raise a WP. Workflow will ensure that authorization for the permit is obtained for each employee ⑦ After the authorization circuit has been respected and all employees on the permit okayed ⑧ the work order can proceed on the specified equipment (or group of equipments) ⑨ In the case of say, an unplanned work order been raised against an equipment that has a permit restriction, the same logic as above applies ⑩ Users can track the status and authorization circuit of a permit at all times. WPs have various statuses such as 0=Raised, 1=not approved, 2=Approved. 3=Closed. The status of the employees and the WP must be logical, for instance, if only some of the employees have been approved but not all, then the status of the WP remains not approved.

Various levels of usage

First of all, the standard Do’s & Don’ts functionality, which most COSWIN users have already seen as part of the Work Order (note that this tab may have been hidden in your installation of COSWIN, talk to you system administrator if we do not see it), can provide support for HSE in a simple manner. Do’s and Don’ts are structured instructions that can be printed out with the WO. They can be defined at the Equipment level.

When actual Work Permits are needed (or an equivalent concept: do not be restricted by the standard terms used in COSWIN – remember that Work Permit is a generic term that may as well refer to Access Permits and also remember that any term can be changed in COSWIN using the Resource Editor), the COSWIN Work Permit functionality should be used:

- The first level of utilization is simply to get the WP printed together with WO. The WP can then follow an approval route outside of COSWIN. This can easily be setup by customers.

- A second level of utilization would be to keep track of the WP status and approvals in COSWIN, for follow-up and auditing purposes, but without constraining the WO process to much. Experience has shown, especially in China, that interlocked approvals in the CMMS (e.g. the WO cannot be released until the WP is approved) are very likely to block the process altogether, resulting in the creation of parallel paper systems. An experienced COSWIN user with access to the system document should be able to setup the system without difficulty.

The next levels of utilization may require additional help from Siveco, in terms of defining the work process, configuring the system and ensuring its smooth implementation:

- In companies where safety management has to be computerized, it is possible to enable constraints between WP and WO in COSWIN. The best example of this may be Singapore MRT (the city-state’s metro system) which uses the full extend of COSWIN functionality to manage Track Access. COSWIN is interfaced with the physical access control system based on smart cards. Unless the Track Access Permit has been approved in the system, the worker will not be allowed access to the tracks.

- Finally, note that the WP functionality can easily be interfaced with external systems using COSWIN standard data exchange tools. For example our customer Kerneos Aluminates Technology in Tianjin uses a globally centralized Work Permit system, based on digital signatures, which exchanged WP data with COSWIN.

Conclusion

Most companies still manage safety, lockout and work permits instructions outside of the CMMS: this is mostly due to existing habits based on paper systems, but also to insufficient knowledge of COSWIN, which is often seen as purely a “maintenance system” i.e. work orders. The immediate benefit of using the basic WP in COSWIN would be to help rethink, formalize and structure the process of managing safety. Additional benefits include traceability and ultimately replacing the paper trail for regulatory inspection purposes: it is important to note that the Chinese authorities can accept computerized records instead of the traditional papers. In its most advanced versions, the WP system is a critical tool to ensure safety (example of the metro).