Release of bluebee® X the new generation Smart O&M platform

On November 13, 2020 Siveco, the pioneer of Smart O&M, officially released the new generation of its flagship bluebee® software suite, code-named bluebee® X, during its annual customers event in Kunshan, China.

read moreA flurry of activity aimed at promoting good asset management practices

As part of its COVID-19 crisis plan, announced in February 2020, Siveco has increased its investment in the Chinese market. The company made the strategic decision to provide extra funding not only for R&D but also for marketing activities.

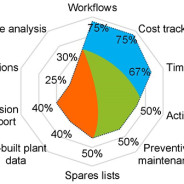

read moreHow to measure the success of a CMMS implementation

It is often said that maintenance digitalization projects have a very low success rate. Often managed by IT, most CMMS or EAM projects result in systems that maybe work from a technical standpoint (users can login and access the various functions) but cannot be used in practice (data not accurate, no useful reports, inconvenient user interfaces). Obviously such system does not help the company achieve any industrial improvement.

read morePredictive maintenance: information overload, the Cassandra effect

This is the second article in a series on the hot topic of Predictive Maintenance, drawing on the practical experience of Siveco working with maintenance improvement in China and the Asia region in the past 20 years. As seen in the first article Predictions on Predictive Maintenance: it will fail… unless., ‘right data’ is better than ‘big data’.

read moreWelcome to the bluebee® club!

As the COVID-19 crisis has already lasted over 9 months, although there are signs of economic recovery in China, many companies have been severely impacted in particular SMEs. Maintenance improvement is becoming a priority again (our marketing hotline is receiving more calls than ever before) but expensive 4.0 budgets are getting cut. To meet the immediate needs of SME clients, Siveco has repackaged our proven solutions and services under the new “bluebee® club” concept.

read moreSupporting the lifecycle of energy infrastructures with Smart O&M

In the era of industry 4.0, most energy projects in Asia still enter commercial operation without a maintenance system in place. Instead, the operation and maintenance (O&M) team, already busy with start-up issues, struggles to gather technical documentation, to define paper-based procedures and when time allows, years later, to implement computerized system.

read more