Essilor speaks on its continuous improvement of equipment maintenance with Smart O&M

In these videos, Chen Xiaoke, Maintenance Manager of Shanghai Essilor Optical Company’s Prescription Export Lab (known as CHLOE) shared his experience of continuous improvement of equipment maintenance in Essilor.

read moreThe maintenance assessment: a stepping stone for improvement

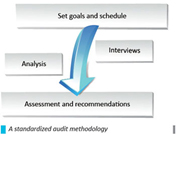

Maintenance assessments (sometimes called “audit” although we prefer the term “assessment”) represent a growing part of our business in China. This article will explore the principles, practice and benefits of such assessments.

read moreObtaining ROI from maintenance optimization at mobile phone giant in Beijing

This case study, written before the acquisition of Nokia by Microsoft, represents a great example of optimizing maintenance costs in tough economic times. Siveco’s first encounter with Nokia was during the company’s heydays, when the LEED Gold certified Nokia Beijing campus was the center of attention in the Facilities Management community.

read moreQ&A on optimizing operations in tough economic times

This month’s Reliability article will summarize two of the presentation’s key points, which were not covered in the original article. It will also answer some of the most frequent questions that were asked during the event.

read moreEmbracing maintenance KPIs leads to improved performance in the challenging shipbuilding industry

Yangzhou Dayang Shipbuilding Co., Ltd. (“Dayang Shipyard”), is the largest shipyard in Sinopacific Shipbuilding Group and a National First Class I Level steel shipyard.

read moreIndustrial Excellence in China: Lean Manufacturing, a Giant with Feet of Clay

Maintenance is seldom recognized as a key aspect of plant operations in China – how many articles have you read on the subject? Trendy topics such as Green Technologies or Lean Manufacturing are almost never seen in relation to maintenance, which however plays a critical role in their successful implementation.

read more