Avoiding pitfalls when implementing WCM / TPM in China

Companies trying to implement World Class Manufacturing (WCM) or Total Productive Maintenance (TPM) or Lean Manufacturing in China, usually as a part of a corporate roll-out, face specific challenges, which may differ from those observed in Japan or in the West.

read moreBaosteel Packaging improves reliability with Maintenance 4.0 (case study video)

The film demonstrates how Siveco solutions support the implementation of the maintenance strategy defined by Baosteel Packaging, with comprehensive and standardized business processes at working level and at management level, based on Coswin 8i and bluebee®.

read more2020 Customer Satisfaction Survey Report

In this month’s newsletter, we are pleased to share the results of our 2020 customer satisfaction survey, which focuses on Support and Product for customers under support. The purpose of the survey is to strengthen our relationship with customers, identify their long-term needs and constantly improve our products and customer services.

read moreCommitted to China and the Belt & Road

It was my great honor to conclude this year’s Siveco China customer event in Kunshan on November 13. In true Siveco fashion, we let our customers speak at the event! Many thanks to those who shared their experience, their success with our approach, which combines maintenance know-how and innovative tech.

read moreA flurry of activity aimed at promoting good asset management practices

As part of its COVID-19 crisis plan, announced in February 2020, Siveco has increased its investment in the Chinese market. The company made the strategic decision to provide extra funding not only for R&D but also for marketing activities.

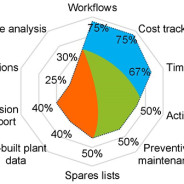

read moreHow to measure the success of a CMMS implementation

It is often said that maintenance digitalization projects have a very low success rate. Often managed by IT, most CMMS or EAM projects result in systems that maybe work from a technical standpoint (users can login and access the various functions) but cannot be used in practice (data not accurate, no useful reports, inconvenient user interfaces). Obviously such system does not help the company achieve any industrial improvement.

read more