Flipping the script on Industry 4.0: why 61% of projects fail and how to fix it

The vision of Industry 4.0 is promising, yet many projects falter in reality due to issues in processes, personnel, and management. Siveco China and Bluebee Technologies propose a different approach: instead of presuming organizational maturity, they cultivate it through the bluebee® Smart O&M solution. By placing people at the core, integrating the ISO 55000 standard, and providing continuous support, the solution helps build capabilities through practice, enabling enterprises to steadily advance their digital transformation.

read moreA quick guide to Smart Maintenance features vs. ISO 55000

Based on the ISO 55000’s asset management framework, this article provides a comparative analysis of smart maintenance technologies in areas such as mobile solutions, IoT integration, AI analytics, and ESG support. It highlights application challenges and emphasizes aligning technology with business strategy, leveraging historical data for predictive maintenance, and supporting sustainability goals to achieve long-term asset management optimization.

read moreStable Operations: How a Leading Hazardous Waste Treatment Company Uses Smart Technology to Navigate Industry Downturns

leveraging best operational practices from SUEZ Group and Siveco China’s ISO 55000-based maintenance management methodology, the plant successfully launched the Smart Operations and Maintenance (O&M) system, based on Coswin 8i.

read moreCross-department cooperation at its best: Smart O&M (CMMS) implementation at Hebei CASDA Biomaterials

The case study of Hebei CASDA is not only a successful digital transformation practice, but also a model of cross-departmental collaboration, continuous improvement and innovative management.

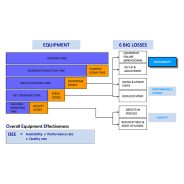

read moreMeasuring OEE in your CMMS/EAM

Should the OEE be calculated in the maintenance system (CMMS/EAM), in production tracking systems (MES, ERP), in monitoring systems (IoT based, SCADA, PLC, DCS)? Or perhaps in an external system based on data from multiple sources either automatically or manually input? There is no right or wrong answer, it all depends on your current needs, situation, and IT landscape.

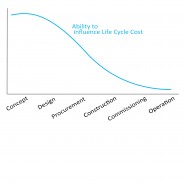

read moreThe earlier the better: advantages of Smart O&M or “turnkey CMMS” in greenfield projects

Experience has shown that the earlier reliability and maintainability are taken into account in a construction project, the better.

read more