Smart Water with Chinese Characteristics: A Practical Guide for Infrastructure Owners

The article is based on a presentation we gave at the last International Water Association conference in November 2019.

The history of O&M best practices in western water companies can be traced back to Roman magistrate Sextus Julius Frontinus’s “De aquis urbis Romae”, nearly 2000 years ago. On the other hand, Chinese water companies tend to be considered laggards by international and domestic observers alike. Yet, they are moving faster than anyone had expected in terms of Smart Water. On the IT front, China has in recent years been recognized as a technology powerhouse. On the operational front, not only China operates water infrastructures on an unprecedented scale, it is also playing a quiet but significant role in the development of the ISO 55000 Asset Management standard (also known as GB/T 33172 in China).

This article draws on the “Maintenance in China” study conducted by Siveco China and the Sino-European School of Technology of Shanghai University, which surveyed around 250 infrastructure projects in China (most of which water & waste), and additional research conducted at the school on related topics in 2018 and 2019. These academic findings are complemented by in-depth O&M audits of water and other utility companies, all over Asia, conducted by maintenance consultancy Siveco China. They are illustrated by real-life case studies of successful “Smart O&M” projects in China, showcasing advanced technologies used to address strategic operational needs.

Findings

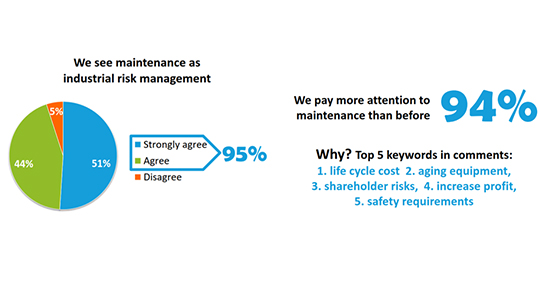

Survey responses show much greater awareness of the importance of maintenance in relation to risk prevention in mainland China, a phenomenon driven by government campaigns around sustainability, digitalization and much stricter HSE regulatory enforcement.

Figure 1. Survey findings: maintenance as industrial risk management

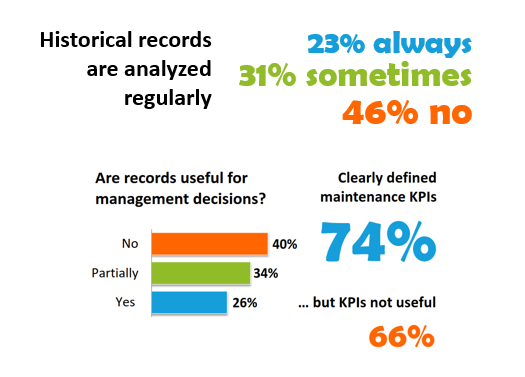

Execution however is still lagging: decision support is a weak area, making it difficult to close the “feedback loop” as per ISO 55000.

Figure 2. Survey findings: closing the feedback loop

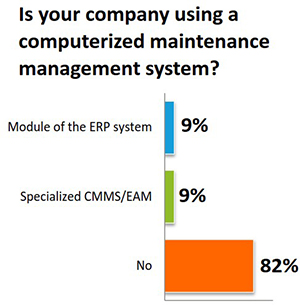

In China, penetration of IT systems for O&M remains low.

In-depth onsite audits of utility companies, all over Asia, having implemented IT solutions often known as “EAM” (Enterprise Asset Management) consistently show major gaps between their strategic needs (as per ISO 55000) and the actual coverage achieved.

Figure 3. Typical coverage of “EAM” systems (achieved / goal in %)

Virtually all EAM projects are driven by IT departments and conducted by IT vendors with limited understanding of O&M, hence this focus on non-strategic “administrative” aspects of the projects.

Case studies

In the past few years, more and more Chinese water companies, with a growing understanding of the strategic role of O&M and strong government incentives, have been implementing digitalization projects guided by ISO 55000 rather by than administrative or IT needs, essentially focusing on the gaps observed in traditional IT “EAM” projects.

•

PPP for the city of Yuyao (pop. 850,000).

•

Setup group-level maintenance strategy based on ISO 55000.

•

Pilot implementation through Smart O&M in Yuyao.

•

Lifecycle strategy for the ongoing phase 3 construction.

•

Followup of commissioning using “bluebee” mobile.

•

Integration with 3D BIM for O&M.

•

Progressive informatization of O&M, first with water quality (the city’s priority).

•

Later for inspections and maintenance; for their joint-venture water company; for secondary water supply, etc.

To see the bluebee® solution in action, see “Demo movie: how bluebee® supports water infrastructures to close the ISO 55000 feedback loop”.

Guidelines & conclusion

From this experience, practical guidelines have been defined for the design, implementation and long-term stewardship of Smart Water technologies.

For green-field projects:

•

Incorporate Smart O&M requirements in construction tenders.

•

See Smart O&M as a lifecycle management tool, in particular utilize BIM for O&M to facilitate the handover of as-built data from construction to maintenance and to enable O&M “best practices” from day one.

For existing facilities:

•

Aim to achieving rapid, measurable, operational benefits.

•

Close the ISO 55000 loop with mobile solutions for technicians (paperless) and visual management (large touchscreens).

For all projects:

•

Focus on the gaps observed in traditional IT/EAM projects using ISO 55000 as reference.

•

Focus on people (technicians and decision makers) rather than processes or technology.

•

Use ISO 55000 to drive the project and avoid complexification or confusion (often seen with IT/admin and sometimes with automation/supervision needs or solutions).

This approach developed in mainland China has been successfully exported on the Belt & Road (e.g. power plants built by Chinese and Korean EPCs in Southeast Asia, Africa and South America). In terms of technology, mobility and BIM for O&M concepts created by Siveco in China are now also being used in European infrastructure projects (e.g. French railway company).