Never too small for a CMMS

Smaller companies have to do more with less

Many companies feel that their facilities or their organization are too small to implement a CMMS or to hire the services of a consulting firm like Siveco. This is especially the case in China, where small to mid-size factories may use second-hand equipment (low accounting value) and rely on relatively cheap labor (low perceived maintenance cost). Another China-specific phenomenon is that rather large companies may still consider themselves small…

Nevertheless, these small companies are facing the exact same maintenance problems as their larger counterparts, but with additional challenges: lack of funding, lack of central corporate support, higher turnover, difficulties to recruit experienced personnel resources, etc. This often results in an even more shoestring firefighting approach than what is usually found in the industry in China…

Siveco customer Karlsson Spools in Kunshan, only 2 maintenance employees, benefits from CMMS project

On the other hand, smaller companies have more flexibility to make decisions, less corporate constraints, which can result in quick efficient projects designed to address the real needs of the local organization, while their large MNC counterparts may be struggling for years just to explain to headquarters why they need a project. This represents an opportunity for small agile manufacturers to get ahead of larger corporations in the field of maintenance: the experience of Siveco with mid-size companies reflects this.

Maintenance metrics are independent from company size

The metrics of maintenance are the same for any size of business. The most basic maintenance indicators are financial values divided by Asset Replacement Value, i.e. they are adjusted based on company size.

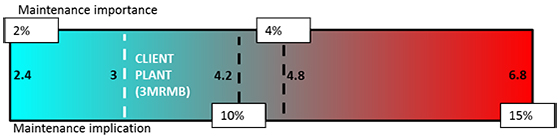

Benchmarking of key metric (figures are in millions RMB)

In this previous Reliability article, we explored some of those metrics which are applicable to any company, any asset. The only difference is the size of the resulting project, proportional the ROI that can be achieved, itself related to the value of avoidable losses. Large companies usually have higher potential losses (but not always, it depends on what business you are in).

The most typical mistakes companies make, small and large corporations alike, is to only look at their direct costs: salaries of maintenance staff (often appallingly low), spare parts (often localized), contracts (often cheap local unqualified service providers), while ignoring losses (sometimes because they have not been any major incident so risks and potential losses are still invisible).

Here smaller companies have an advantage that big faceless corporate may not have: they tend to have a longer-term view (especially for family-owned businesses vs. stock-listed ones), to be closer to their process and their machines, to have a real top-management involvement in the business and a lower top management turnover (while 2-3 years expat contracts are the norm in MNCs). This makes it easier for them to see the potential losses.

Work smarter not harder

Faced with the impossibility to throw more resources at the challenges they meet, SMEs have to work smarter than MNCs. This is where the CMMS comes into play, as the tool to structure the maintenance organization and to measure losses and gains in order to make better decisions.

This is why the typical Siveco project for SMEs is built around two main components:

• A consulting service package, aimed at introducing best maintenance practices (plant documentation, failure codes, KPIs), training the maintenance team, standardizing work processes, initializing and optimizing over time the maintenance strategy (which usually means preventive maintenance).

This could take the form of training services (sending your people at attend classes) or pure consulting, which almost always fail to deliver results in China (people tend to think what you learn is class doesn’t apply to real life, employees change job as soon as they gained new qualifications, new work processes quickly disappear once the top manager is not involved in every single step of the process…).

The Siveco approach is to use the CMMS project to manage all the activities above, giving a tangible, concrete, aspect to what most local staff would otherwise consider as “hot air”. The CMMS acts as a structuring tool, resulting in a comparatively lower total cost compared to pure consulting (which is counterintuitive, but proven many times over by China experience).

Furthermore, once the Siveco consultants have left (they come back on a regular basis during the Enhanced Support period), the CMMS remains, producing regular KPIs, ensuring sustainable results.

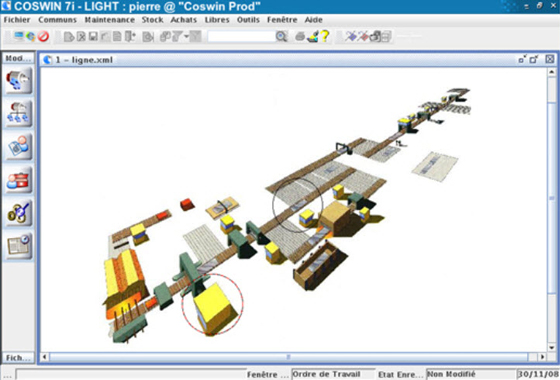

• The second component is of course the CMMS itself. For SMEs, we most often use Coswin Light, the preconfigured prepackaged version of Siveco’s leading CMMS Coswin (see Tips & Tricks article for more on Coswin Light). Coswin Light is a simple yet complete CMMS that supports all activities above. It is designed for the smaller budgets of SMEs and has built-in limitations that are of no-consequence to SMEs (limited database size, limited interfacing capability). If the company grows much bigger, the system can easily be upgraded to a full Coswin.

This could take the form of training services (sending your people at attend classes) or pure consulting, which almost always fail to deliver results in China (people tend to think what you learn is class doesn’t apply to real life, employees change job as soon as they gained new qualifications, new work processes quickly disappear once the top manager is not involved in every single step of the process…).

The Siveco approach is to use the CMMS project to manage all the activities above, giving a tangible, concrete, aspect to what most local staff would otherwise consider as “hot air”. The CMMS acts as a structuring tool, resulting in a comparatively lower total cost compared to pure consulting (which is counterintuitive, but proven many times over by China experience).

Furthermore, once the Siveco consultants have left (they come back on a regular basis during the Enhanced Support period), the CMMS remains, producing regular KPIs, ensuring sustainable results.

• The second component is of course the CMMS itself. For SMEs, we most often use Coswin Light, the preconfigured prepackaged version of Siveco’s leading CMMS Coswin (see Tips & Tricks article for more on Coswin Light). Coswin Light is a simple yet complete CMMS that supports all activities above. It is designed for the smaller budgets of SMEs and has built-in limitations that are of no-consequence to SMEs (limited database size, limited interfacing capability). If the company grows much bigger, the system can easily be upgraded to a full Coswin.

A strong warning here: many smaller companies have already understood all the above and decided to purchase a cheap CMMS, without consulting support (perhaps only training). Such an approach invariably fails in China (and has not proven very successful elsewhere either). CMMS alternatives perceived as “cheap” include Access-based solutions (which can be developed in-house), local CMMS ( (often cheaper than you think considering they usually give 25% back to your own staff in cash), small international CMMS suppliers (often of the “we send you a CD, you install yourself” variety). Our experience encountering countless such projects is that they take many years, seldom achieve anything usable and more often than not the CMMS box ends up on a shelf. These “cheap” projects end up costing much more in terms of losses.

SMEs reap more benefits

While the main benefit will always be in terms of losses avoidance, SMEs can reap more benefits from the CMMS project, due to their specific needs and challenges:

Improve work efficiency, especially in terms of administrative support needed to answer maintenance improvement questions: when and where did we purchase this part? how much did it cost? what was the delivery lead time? when did we last replace this component? is the equipment still under warranty? what are the terms of our warranty or maintenance contract? how much did this equipment cost over its lifetime? did this failure happen before? and how did we fix it last time? etc. A well-implemented CMMS will answer all the questions in just a few clicks.

Insure the company against staff turnover: when employees leave, which for some companies happen often, their know-how and memory of the machines leave with them. As a result we often see factories where no know-how has been accumulated. Even if workers stay, management turnover results in the same problem. The CMMS ensures that the entire history of the plant remains in place; it is also a tool to train newcomers.

Take a first step

An easy first step to take is to complete our online survey, which will give us a good idea of where you currently stand. The survey is here:

http://www.sivecochina.com/Survey/Limesurvey/index.php?sid=71293&lang=en

http://www.sivecochina.com/Survey/Limesurvey/index.php?sid=71293&lang=en

Ideally, you should also send us a few figures so we can size up your company properly: the asset replacement value of the plant, or alternatively the initial investment value, the current yearly maintenance cost (or your best guess for it, listing whether or not you have included salaries, parts and contracts), number of total staff, maintenance staff, and a brief description of the plant and its machinery. You can send this to info@sivecochina.com.

Based on the survey response and other details, one of our consultant will get back to you shortly for a first discussion on the phone, during which we will together evaluate whether it makes sense to proceed to a site visit.

Tags: Coswin Light、SMEs