2019 Customer Satisfaction Survey Report

In this month’s newsletter, we are pleased to share the results of our 2019 customer satisfaction survey, which focuses on Support and Product for customers under support. The purpose of the survey is to strengthen our relationship with clients and constantly improve our products and services.

read moreSmart O&M in Energy industry: interview of Siveco China’s COO by EventLinker

Ahead of the Future Energy &Tech Investment Forum at Spaces Sun House in Hong Kong, Siveco China COO Guillaume Gimonet was invited to interview with EventLinker, a professional tech and innovation event organizer, and shared his point of views on the importance of Smart O&M technologies in optimizing the management of modern high-tech utilities.

read morePredictions on Predictive Maintenance: it will fail… unless

There has been a tremendous fuss about Predictive maintenance this summer. Consulting firms and sensors suppliers seem to rediscover maintenance after so many years of staying carefully away from this complex – and often non-bankable – topic. Time has changed now, and thanks to the limitless power of AI and IoT ubiquity, the maintenance nut will soon be cracked (possibly by a cobot nutcracker).

read moreImprovement from CMMS: what do best-in-class companies do

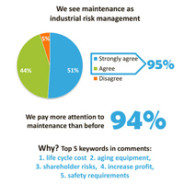

The last “Maintenance in China” survey, conducted in 2017 and covering over 450 companies, provides useful insights. We republish here a summary of the findings and expand on what best-in-class companies (those with the best performance according to their survey results) have done to obtain such results.

read more2018 Customer Satisfaction Survey Report

In this month’s newsletter, we are pleased to share the results of our 2018 customer satisfaction survey, which focuses customers under support. The purpose of the survey is to constantly improve our customer service and to identify customer long-term needs.

read moreAnother industrial disaster, another wake-up call for maintenance

An explosion ripped through Chenjiagang Chemical Park in Yancheng, Jiangsu province on March 21, which killed 78 people and seriously injured 79. A few months before, at 0:41 on November 28, 2018, an explosion occurred near Shenghua Chemical in Zhangjiakou City, Hebei Province: 23 were killed and another 22 injured.

read more