Latest issues

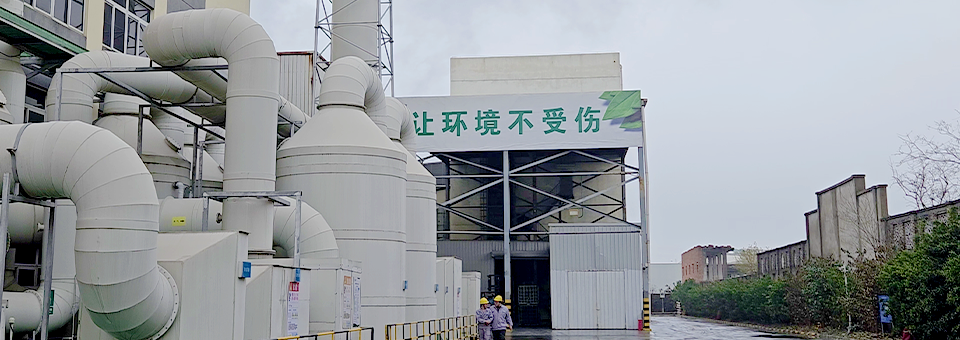

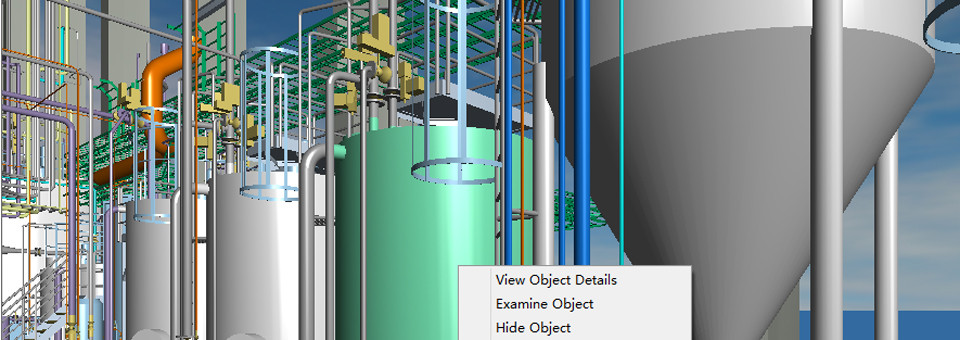

GSN setting new benchmark for facilities management using bluebee®

bluebee® now allows GSN to systematize all its maintenance processes. Centralizing the information in a closed system, by creating a database of the equipment, and combining it with the VDMA guidelines guarantees that all maintenance operations are planned and performed timely. By granting its client an access to the system, GSN offers them an unrivalled level of transparency.

read moreSummer collection

Welcome to the Summer 2017 edition of our “Maintenance in China” newsletter! As usual we wanted to take it easy during summertime, so we chose to collect some of our most popular articles. I would especially like to highlight the Reliability piece A practical bluebee®-driven PAS 55 / ISO 55000 implementation. As many of our readers already know, since May 1, 2017, ISO 55000 has become effective in China as a local standard GB/T 33172.

read moreSiveco mid-term management meeting in Suzhou

On July 14, Siveco China held its mid-term management meeting at the Pan Pacific Hotel in Suzhou. July being an extremely busy month, team members flew in from Hong Kong, Zhongshan and Beijing, in addition to Shanghai. The exchange session proved to be very fruitful with many improvement ideas, which will be put into practice into daily operation.

read moreFrench National Day celebration at Siveco Shanghai

July 14th is the day French people celebrate for their Revolution. As per our tradition, the Siveco team held a party at the Shanghai office. Led by Bruno Lhopiteau, our General Manager, we sang the French national anthem and various revolutionary songs together and enjoyed cheese and champagne! In this joyful atmosphere, may the Sino-French friendship last forever!

read moreDriving improvement with Siveco’s Enhanced Maintenance services

Siveco China has for many years already established a professional Customer Support Organization: putting customers as the center, providing efficient customer support focused on improving maintenance management, with high customer satisfaction results. As of today, around 450 sites are enjoying Siveco China’s Support services, under two formulas: Standard Support or Enhanced Maintenance Service.

read moreDaramic Thailand towards World Class Maintenance

For over 85 years, Daramic has led the way in developing new and innovative technology for the lead acid battery market. With headquarters in Charlotte, North Carolina, USA, Daramic today supplies nearly 50% of the world’s demand for high performance polyethylene battery separators to the lead acid battery industry. Daramic Thailand operates the largest and most advanced polyethylene separator manufacturing plant in Asia, located in Prachinburi.

read more