Latest issues

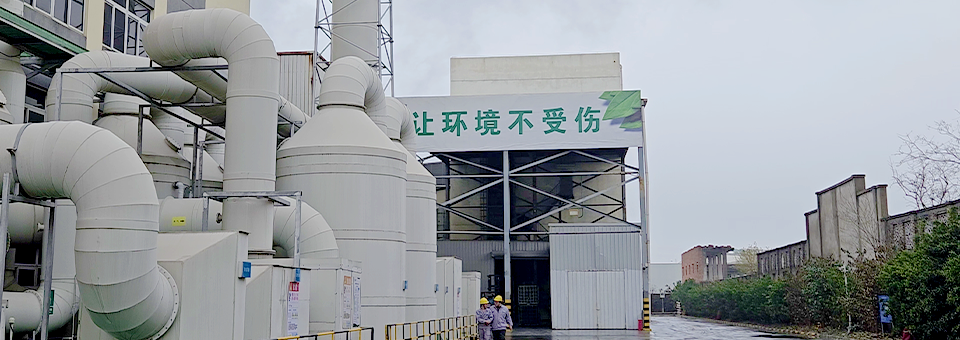

Smart O&M as a tool for continuous improvement at BEGSE

By defining the “Core Model”, Siveco China has established a comprehensive maintenance management system for BEGSE, including technical data management, HSE management, preventive work planning, spare parts management, procurement management and decision support.

read moreA summer with Smart O&M in China and on the Belt & Road

During the summer, the Siveco China team has been busy on many projects in China and overseas. As the world saw a resurgence of Covid-19, affecting travel in parts of China, and more heavily impacting other countries, we continued to try to proactively address our clients’ needs.

read moreOld friends reflect on maintenance audits

During the Labor Day holidays, old friends met together, my old colleagues who have been engaged in researching and delivering Asset & Maintenance Management solutions since the late 1990s. They have taken part in many projects in the power, chemical, paper and environmental industries. During our gathering, we talked a lot. I have summarized here the hottest issues.

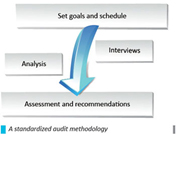

read moreThe maintenance assessment: a stepping stone for improvement

Maintenance assessments (sometimes called “audit” although we prefer the term “assessment”) represent a growing part of our business in China. This article will explore the principles, practice and benefits of such assessments.

read moreImplementing ISO 55000 in Capital Eco-pro Group (case study video)

Capital Eco-pro Group, one of China’s largest environmental groups, operates public-private partnerships (PPP) water companies all over the country. To further enhance the reliability of its service to municipalities across China, Capital Eco-pro Group launched a project to optimize its Asset Management system, based on the ISO 55000 international standard.

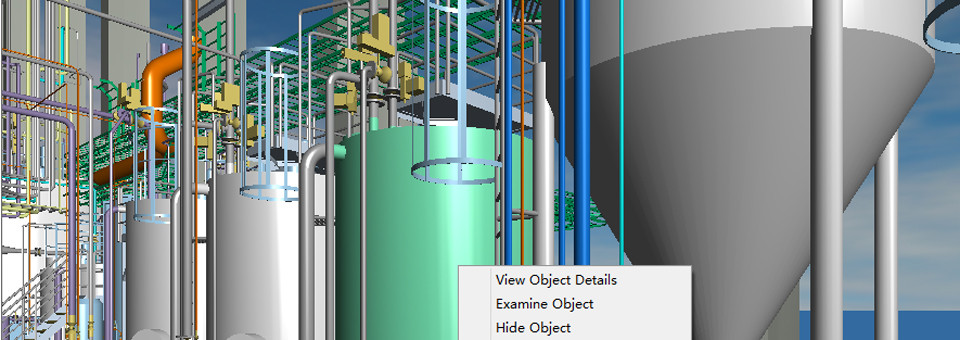

read moreSiveco China & Organica team up to deliver O&M Digital Twins for Wastewater Plants

Organica (www.organicawater.com), a global provider of innovative wastewater treatment solutions, and Siveco China, a pioneer of Smart O&M with a long presence in the Chinese water market, have launched a partnership to deliver Digital Twin solutions for the Operation & Maintenance of wastewater treatment plants.

read more