Quick benefits from underutilized COSWIN functionalities: Hazard Report

This article is the third in a series aimed at familiarizing our readers with lesser-known COSWIN functionalities, which can easily be configured by customers themselves to bring immediate benefits. Previous issues covered Contract Management and Work Permits.

The Hazard Report is perhaps one of the most interesting COSWIN features, as it essentially links operations to maintenance, in more ways than the name “Hazard” seem to indicate (implying a reference to safety). This article will explain the basics of the Hazard Report functionality, elaborate some of its real-life implementations and present a example (application to quality at cable manufacturer Acome Xintai).

Hazard Report

The hazard report is available for managing incidents or events that require attention. Its purpose is to lead to an action plan so that the incident does not repeat. The module is used to manage the complete cycle of a hazard report: create, update, delete, the effects, the recommended actions, and the follow up. Hazard reports are created against equipments (but this is not mandatory) and COSWIN stores all hazard report details. It also keeps a list of recommended actions and follow-up actions. ① An incident is noted ② A hazard report is created with various fields indicated below ③ The hazard report can generate various documents or transactions: Job Requests, Work Oder(s) or Purchase Order(s) to COSWIN Stock & Purchasing.

“Hazard”? What’s in a name.

Two things that should never be forgotten with CMMS and COSWIN in particular:

| (1) | The people who developed the system had to choose names for the software functionalities (menus, screens, fields, etc.). While a generic name may cover all possible user of the functionality, it may not sound meaningful to users. On the other hand, a meaningful name may restrict the way people understand the functionality. COSWIN’s Hazard Report is a perfect example of that. | |

| (2) | Using COSWIN Resource Editor, any name in the system can be changed, in less than a minute. |

For example, the “Hazard Report” can be changed to “Shift Report”, “Quality Report”, “Operation Report” or anything else.

The choice of “Hazard Report” highlights the possibility to use the functionality to report safety issues and launch corrective actions, in the form for example of a Job Request to the technical department, a direct Work Order or even a Purchase Request.

The same exact functionality could also be used for what is commonly called “Shift Reports” or “Shift Log”: during or at the end of a working shift, the shift leader reports what has happened. The purpose is to inform the next shift or launch actions by maintenance or other departments.

The same principle could be applied for reporting quality problems by production, through “Quality Reports” or “Defect Reports”: production logs quality problems and suggests or requests actions to be taken.

You can imagine other applications. In all cases, the “Hazard Report” functionality – under this or another name of your choosing – ensures traceability: the incident (a production event, a quality problem, a safety risk etc.) is reported (who, what, when) and linked to an action (JR, WO or PR). It can then be followed up, measured and traced back to the initial event.

This process may or may not even be related to the maintenance department. It doesn’t matter, it can still be managed in COSWIN.

As readers will have understood, we have just described a very important business process that ties together technical events and their consequences: an essential element of regulatory compliance and business management, usually not managed in the CMMS.

An example of application: quality management in Acome Xintai

Acome Xintai Cable Co., Ltd. is a producer of RF cables (used in antennas), located in Shandong province. The semi-continuous manufacturing process requires a strong involvement from the maintenance team. During the initial audit conducted by Siveco at the beginning of the project, important savings opportunities were identified in using COSWIN to support Acome’s technical team for the resolution of quality problems.

In order to carry a given signal properly, the cables have to respond specifically to certain frequencies: may the cable be too thick or too thin (a few micrometers) at some point, the frequency response will show a peak out of the specified range and the whole batch will have to be scrapped.

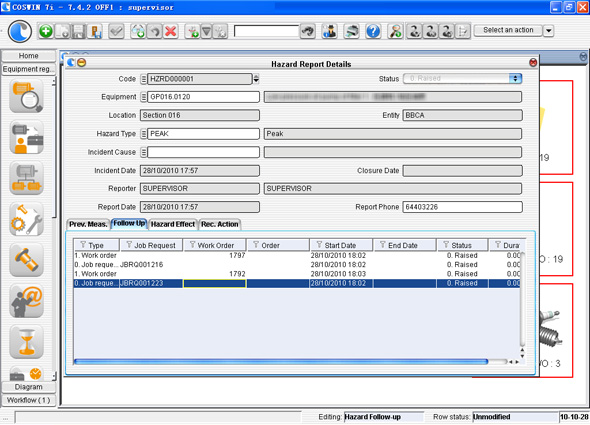

When such defect is detected, a Hazard Report is raised in COSWIN, containing all related information such as the peak value in MHz. An inspection is then carried out on the production line, involving a number of tests: standard exchanges of bearings or gear-boxes, tightening of bolts, adjustment of speed control. For each such modification, a test is conducted, until the cause of the defect is identified. The challenging part of this procedure is that each modification can itself generate more defects – the entire process is very closely managed using Work Orders, one for each modification, all linked to the initial Hazard Report.

Example of Hazard Report at Acome Xintai

A given peak (identified by its MHz value) for a given production line is linked to a unique cause, which makes the historical record an extremely powerful tool to identify the cause of a defect, bringing a costly investigation from 2-3 days down to a few hours. This approach has resulted in important downtime reductions at Acome Xintai, as well as significant direct savings in raw material, energy, etc. In addition the perceived value of the maintenance team in the overall plant performance has been significantly improved!