Maintenance 4.0 for a Sustainable China

Dear Readers,

My first China experience dates back to 1998, when we struggled to implement preventive maintenance at a Suzhou paper mill. I later went on to work for the Chinese power industry. Almost two decades later, we still face the same challenges, trying to break inefficient firefighting habits and to develop sustainable preventive maintenance organizations.

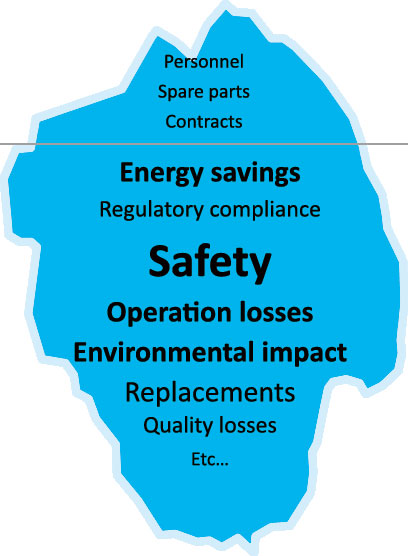

Maintenance as Risk Prevention

Has anything changed? Yes! In the era of the China Dream, there is widespread awareness of safety, sustainability and their relation to maintenance. Maintenance as Risk Prevention. Today’s modern “Industry 4.0” plants require more advanced maintenance skills, not less. Companies have also learnt the hard way that applying Western solutions to Chinese problems usually doesn’t work… and that technology is not a miracle cure.

Facts have proven us right! At Siveco we have over the years developed an offering combining maintenance expertise and innovative technology, designed to address the specific needs of “maintenance with Chinese characteristics”. Siveco made the opposite choice of most suppliers, as we believed in inventing a Chinese way.

Our bluebee® suite of products “for the worker of tomorrow”, putting man, not machine, at the center point, has won many awards. Dozens of clients have enjoyed great results, as shown in our many case studies, and we have even started exporting our know-how, working alongside China-based investors and EPC companies in Asia and Africa.

We call this approach Maintenance 4.0.

It is also the theme of this newsletter in magazine format, with printed copies and pdf versions available (download in English | Chinese version). The first Reliability article goes beyond the marketing hype to explain what Maintenance 4.0 really means for us in China. The second one details how preparing maintenance during the construction stage is key to optimizing the lifecycle of infrastructure and plants. Two case studies illustrate the concept, respectively at Chongqing Sino-French Water and Hanas New Energy LNG plant. The Tips & Tricks article features the integration of BIM (Building Information Modelling) for Maintenance, with an example from oil company CNOOC.

Technology is no silver bullet. It should be designed to tackle the actual challenges we face as we build our China Dream, while taking advantage of the great openness of our people towards innovations. Implementation is never easy, but improvements are achieved at every step in the project, progress is made and we all learn every day. There has never been a more exciting times for maintenance professionals!

Bruno Lhopiteau

General Manager

Siveco China

General Manager

Siveco China