Recap of 2014 projects: example of multisite automotive project

In last month’s newsletter, we recapped some of key projects launched during 2014, with a focus on process plants (power generation, waste and water, chemicals and oil and gas). This month we would like to share another example of multisite maintenance improvement project, this time in the automotive industry.

Although discrete manufacturing is considered less maintenance-intensive than process industries, maintenance can have a tremendous impact. This is especially true of automotive suppliers, facing stringent requirements for quality and just-in-time delivery from automakers, their clients. Siveco has accumulated significant experience in the Chinese automotive industry, with such customers as Allevard-Rejna, Brose, Daramic, Fabricom, Faurecia, Fiamm, Karlsson Spools, Sogefi, Wagon Automotive, ZF Lemforder and ZF Steering Systems.

Magneti Marelli Automotive Lighting (Foshan)

Industry: automotive

Location: Wuhu (2 sites), Guangzhou, Foshan

Scope: multisite CMMS for existing operation, in support of WCM (World Class Manufacturing)

Magneti Marelli (www.magnetimarelli.com), a leading automotive parts supplier, has selected Siveco to implement a maintenance management system to support World Class Manufacturing (WCM) at its Chinese manufacturing plants. The initial project covered three sites: Magneti Marelli Powertrain and Magneti Marelli Automotive Lighting in Wuhu, Anhui province and Magneti Marelli Guangzhou, Guangdong province. This initial project was launched in 2012. In 2014, the Automotive Lighting Foshan plant was also deployed and more projects will follow.

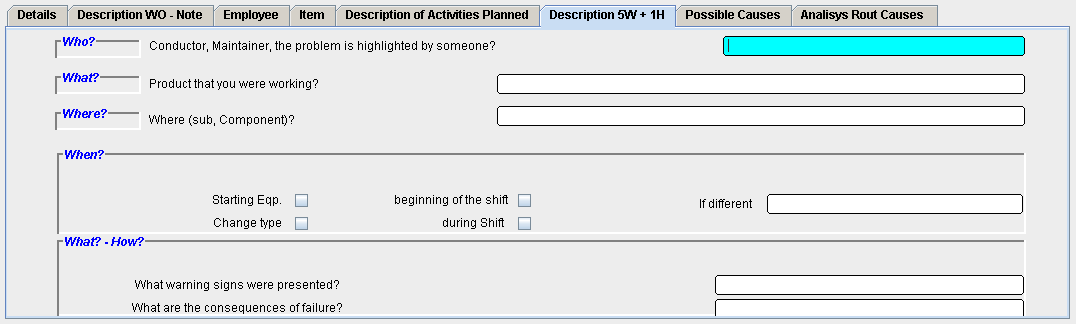

In Magneti Marelli, particular attention has been put on aligning the CMMS project with the “Professional Maintenance” pillar of World Class Manufacturing (WCM) – also known as Lean Manufacturing or Total Productive Maintenance (TPM), a common requirement in the automotive industry. The ISO TS 16949 standard (“Particular requirements for the application of ISO 9001 for automotive production and relevant service part organizations”) also offers strong guidelines for projects.

In the Chinese automotive industry, WCM emphasis is usually put on Workplace Organization and Autonomous Maintenance, with preventive maintenance or “Professional Maintenance” often left behind, which is a common misunderstanding of priorities in WCM… For more on Siveco’s experience with WCM, also see these articles:

In Magneti Marelli on the contrary, the CMMS is designed to drive the build-up of a professional maintenance according to WCM. Here are some illustrations of Coswin functionalities directly applied to WCM:

During 2014, in the automotive industry and more generally with discrete manufacturing plants, Siveco also signed contracts with factories of Alstom, DACC, Essilor, Hanglas Sekurit, Karlsson Spools and Saint Gobain

In an upcoming issue of our newsletter, we will also provide a sample 2014 project in Facilities Management (multisite real estate maintenance), thus concluding our 2014 recaps.