ESG in Smart O&M

For background on this topic, also read Reliability – ESG & decarbonization in operations: the digital gap.

Implementing the action plan and demonstrating compliance

Far from being magically solved by technology, the ESG improvement plan relies on people, engineers, technicians, operators in the plant, managers to make decisions based on facts and figures. Digital initiatives in this field stubbornly focus on monitoring consumption because it is needed but also because it is relatively easy to achieve. In fact, companies did not wait modern Digital Twins with 3D modeling to install automated meters and collect energy data. IoT vendors, once clamoring that “predictive maintenance is a low-hanging fruit” only to realize that it wasn’t so simple, often settled down to automate utility meter reading. Some have now repurposed the exact same solutions as “ESG”, a clever marketing move!

Brose Wuhan, mechatronics components supplier to automakers, did not wait for technology vendors. Facing strong market demand, busy installing new production lines, the company’s General Manager hired consultants to conduct energy and maintenance audits. An action plan was quickly put in place by Siveco China. The plant’s technical data were digitalized, based on which failures and their impact were systematically analyzed. Lubrication and preventive maintenance routines were established. The system monitored the execution of the plans. This continuous feedback loop between plan and action resulted in a 36% reduction of the electricity bill after 6 months. ROI was obtained well within a year. How about the energy meters? They were recorded independently in the existing SCADA system. Equivalent CO2 emissions can be easily computed in Excel at the end of the month.

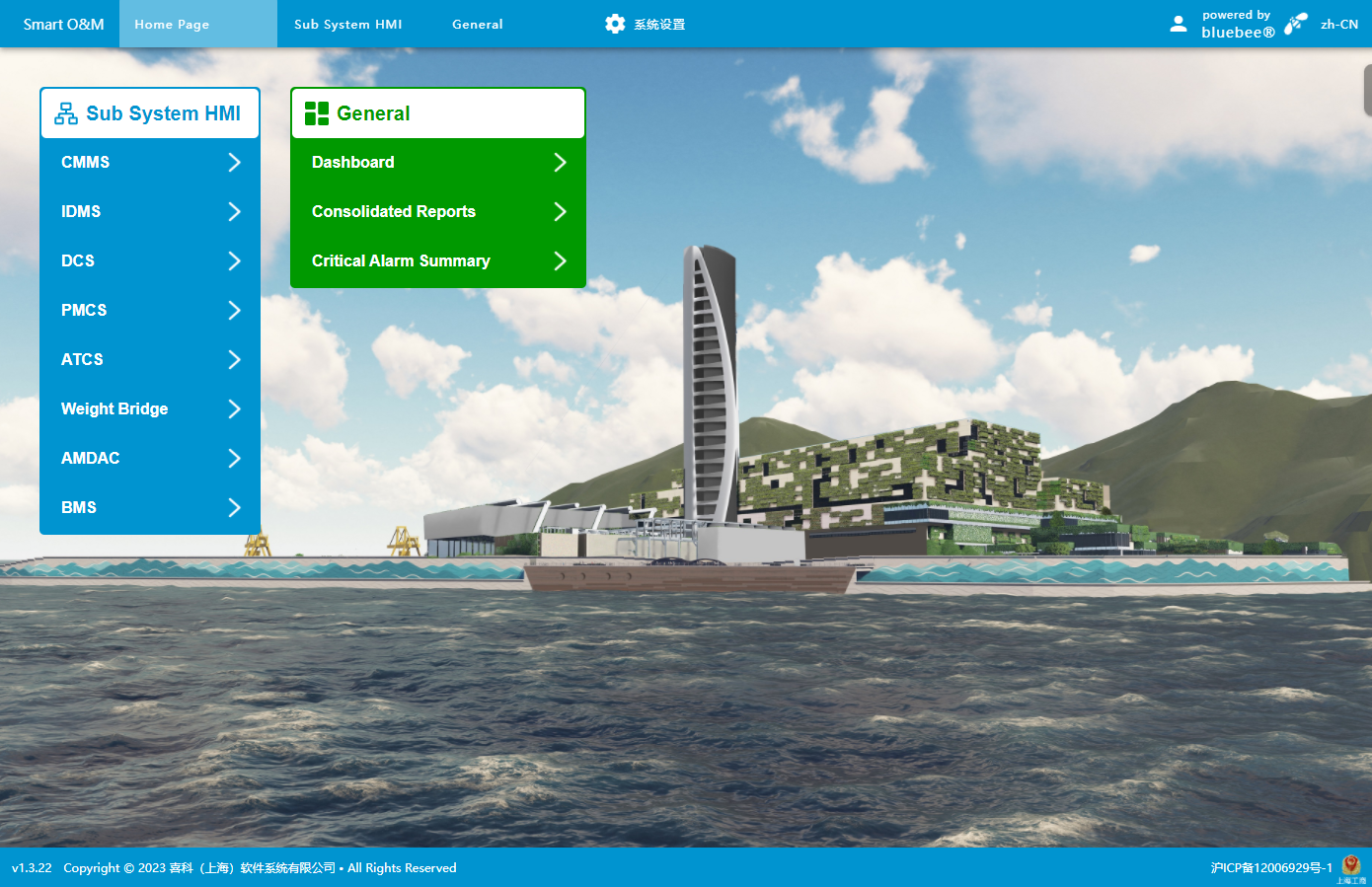

New construction is the ideal time to build a comprehensive digital solution for ESG. For the massive Integrated Waste Management Facilities, a strategic infrastructure currently under construction in Hong Kong, the special administrative region’s Environment Protection Department has specified a Digital Twin for O&M covering maintenance, documentation, environmental compliance, energy efficiency, regulatory reporting. Featuring an embedded BIM model, the system collects data from 9 different subsystems including DCS, BMS, OMCS, ATCS, AMDAC etc. Siveco Hongkong was awarded the contract to deliver the system based on its Coswin 8i maintenance system and bluebee® risk prevention solution. Having successfully passed design approval, the project follows the plant construction schedule, with FAT planned for mid-2023 and commissioning mid-2024.

According to the US Dept of Energy: “O&M measures cost about 20 times less and achieve roughly the same energy savings as energy efficiency upgrades.” As the concept of ESG is of course not limited to greenwashing and marketing, ESG projects and the supporting digital systems cannot be limited to just monitoring and reporting. It is the technical improvement actions taken (or not) in the plant that will ensure actual improvements in ESG. They must and can be managed in a digital solution that will not only monitor energy meters and other sensors (which traditional SCADA could already achieve), not only display KPIs in a beautiful dashboard (which many BI solutions can do), but also and more importantly manage interrelated technical data, help analyze failures and their impact in a systematic manner, define and track corrective and preventive actions including routine maintenance. This feedback loop between work execution and strategy is what will enable continuous improvement, while acting as a brilliant showcase of good ESG practices to all stakeholders.