Old friends reflect on maintenance audits

Author: Paul Wang, Vice President of Siveco China

Dear Reader,

During the Labor Day holidays, old friends met together, my old colleagues who have been engaged in researching and delivering Asset & Maintenance Management solutions since the late 1990s. They have taken part in many projects in the power, chemical, paper and environmental industries. During our gathering, we talked a lot. I have summarized here the hottest issues:

- After having established maintenance principles and standards, why is our equipment failure rate still high?

- With measures in place to control maintenance cost, why does spare parts cost remain so high?

- After the implementation of the maintenance management software, why does unplanned downtime still frequently occur?

- When using an inspection system, why does the inspection completion rate remain low?

Do we have a good way to improve the situation? I recommended the maintenance audit services of my company. After intense debates, everyone agreed that this maintenance improvement method is worth trying. I would like to share how I persuaded these senior maintenance management folks.

First of all, let’s start with the definition of asset management in ISO 55000:

What is asset management?

Systematic and coordinated activities and practices through which an organization optimally and sustainably manages its assets and asset systems, their associated performance, risks, and expenditures over their life cycles for the purpose of achieving its organizational strategic plan.

Optimize the lifecycle of assets – optimize the system balance of asset life cycle management

Thanks to this definition, we can address the pain points listed at the beginning of the article, which then become easier to solve:

- Are the company’s Asset Management objectives reasonable and clear?

- Does the existing organization structure address these objectives?

- Are the existing work order management, preventive maintenance management and spare parts management processes and systems scientific and rigorous?

- Can the existing information system guarantee the accuracy of the basic data and can the operating data be gathered in a complete and accurate manner?

- Can the company comply with the requirements of ISO 55000 to enable all stakeholders to perform their duties as required?

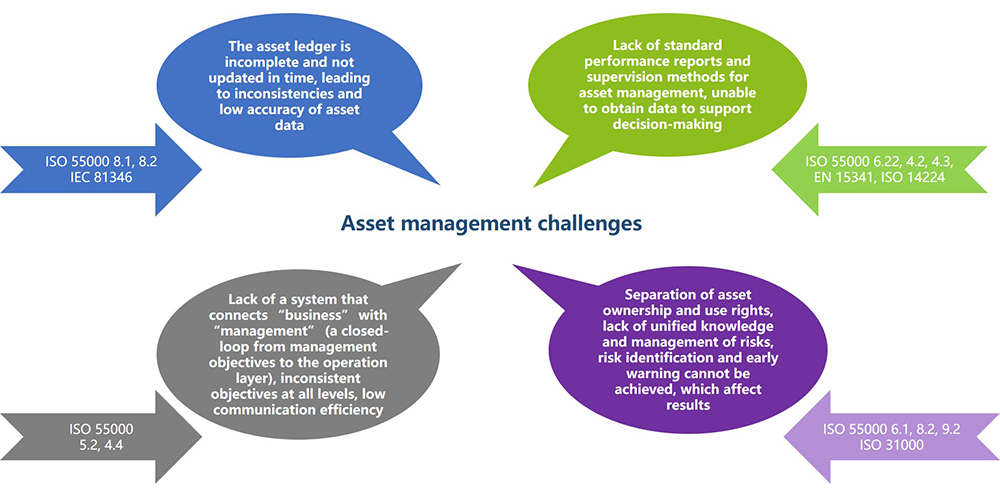

Based on our long on-the-ground experience, we found that the involvement of professional maintenance consulting teams is needed to help companies understand the true management value of ISO 55000 and other related international standards. Based on the client company’s own maintenance management experience, the joint team can identify the pain points. We combine industry knowledge and ISO 55000 and other supporting standards to form corresponding solutions. Here is an example of a preliminary analysis sketch:

Identify and solve pain points according to international standards and methodologies such as ISO 55000

As you can see, different types of problems correspond to different parts of ISO 55000 or other related asset management standards. From this point of view, maintenance audits are like regular medical check-ups. As long as there is an advanced scientific system and standard guidelines, the various pain points of performance, cost control, risk management in enterprise asset management can be identified and fixed.

In the end, such rich discussion at the party made these old friends feel good, taking a weight off their mind. As for me, I had a sense of achievement in this sharing.

In this issue, we will talk more on this assessment topic, you will read our Reliability piece on “The maintenance assessment: a stepping stone for improvement“, Customer story shows Yuyao Capital Water movie case, our Partner article on Organica Water, a global provider of innovative wastewater treatment solutions, Tips & tricks on Flexibility of bluebee® X, and feedback from the French Gala Shanghai 2021 with Siveco China guests.

Enjoy!

Paul Wang

Vice President

Siveco China

Vice President

Siveco China