Smart O&M: the 8 hidden gems of Coswin 8i

This Tip & Tricks is dedicated to 8 advanced yet little-known standard features that make Coswin 8i a true Smart Operation & Maintenance solution, far beyond traditional plant maintenance solutions.

Coswin has always been, by design, much more than CMMS, much more than “EAM”, thanks primarily to its extreme configurability: Coswin users are familiar with the Diagram Editor and Resource Editor, which allow users to build graphical user interfaces, customized screen layout and even completely new functional modules, without any software development.

Especially since the release of Coswin 8i in 2014 and subsequent updates (all customers under support contract enjoy free access to new updates), highly advanced “Maintenance 4.0” features have been included in the standard Coswin solution, covering hot technologies such as IoT, GIS, BIM, mobility, and hot topics such as HSE, linear assets management, metrology and calibration.

Here are the 8 hidden gems of Coswin 8i:

1. Embedded GIS integration

Coswin 8i can display embedded ArcGIS (Geographical Information System) maps, available from the dashboard as well as from equipment and work order screens. Coswin objects (assets, employees, jobs) can be geolocated, as well as work areas. Actions can be performed directly on the map: viewing different layers, clicking on object to display KPIs and opening related Coswin screens (technical details, preventive maintenance plans, create a job request etc.). The GIS function is also available on tablet.

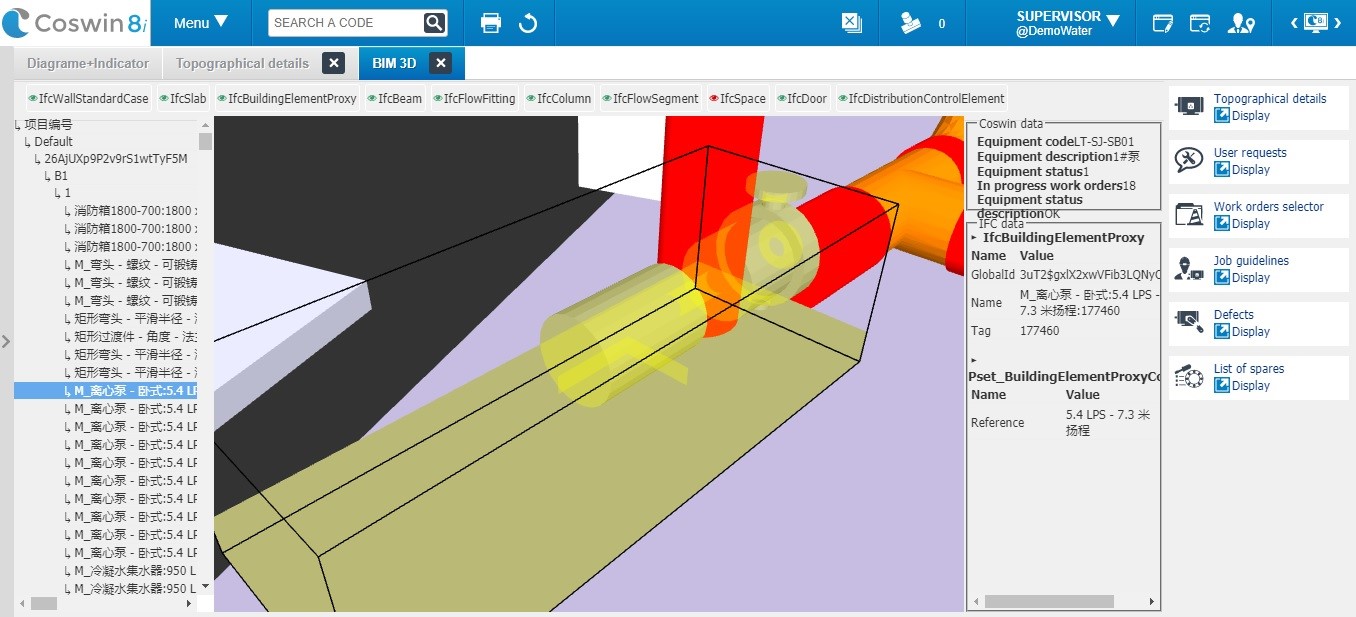

2. Embedded BIM integration

Coswin 8i features a fully integrated BIM viewer based on IFC standard. The viewer allows opening the 3D model directly from relevant Coswin screens, centered on the related equipment object. Users can zoom and navigate, access all related maintenance information, create job requests etc. through a configurable menu. The interface also provides all the necessary import tools to create equipment objects from the BIM model.

3. Tablet mode

Coswin 8i can be used directly on Android or Windows tablet, without any need for additional licenses. Known as the “tablet mode” of Coswin, it is automatically enabled to users accessing Coswin from a tablet. All system functionalities are available to tablet users, without any restriction. Screens are automatically adjusted to match touch-screen usage patterns (larger buttons, simplified screen layout). Coswin Resource Editor can be used to tailor specific screens for tablet users, for example operators performing production reporting on tablets setup on their machines.

Coswin tablet, here also showing the embedded GIS map

For more on Coswin 8i tablet mode, also see: https://newsletter.bluebeecloud.com/en/tips-tricks/using_Coswin_8i_on_a_tablet/

4. IoT integration

Coswin 8i is designed to flexibly integrate with state-of-the-art Industry 4.0 or Internet of Things (IoT) technology. Coswin 8i provides a standard two-way integration toolkit, to receive useful data from Connected Objects (meters, measures, alarms, health reports) but also to allow IoT users to open relevant Coswin 8i screens from their monitoring screens. This integration approach was designed by maintenance experts to bring true value-added to both operation and maintenance users.

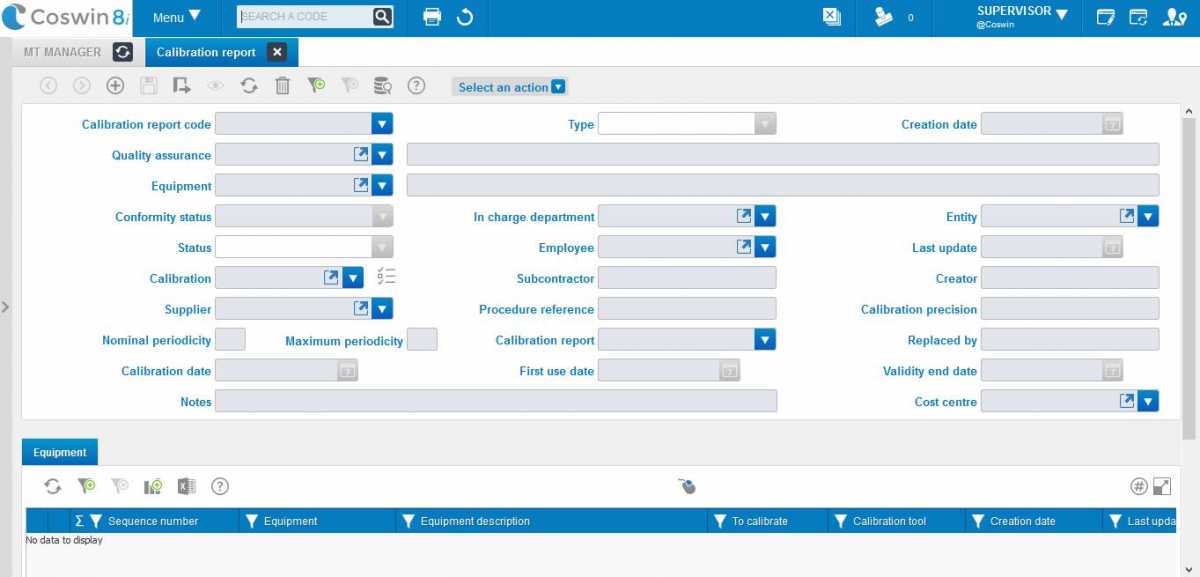

5. Metrology and Calibration

Coswin 8i offers a dedicated metrology module for instrument calibration, measurements, history and traceability, fully integrated with the other Coswin 8i modules. The Metrology module guarantees equipment conformity, control measurement methods and capabilities, track and handle divergences in line with the most stringent industry standards. It is widely used in such industries as nuclear power and other complex, regulated, applications.

6. PPE management – Personal Protective Equipment

Professional risk management and safety is at the heart of business concerns. Coswin 8i, in addition to other safety-related features such as work permit management, lock-out tag-out (LOTO), safety instructions, hazard reports etc., provides a dedicated PPE module to track the usage of Personal Protective Equipment by technician, to manage their condition and lifecycle.

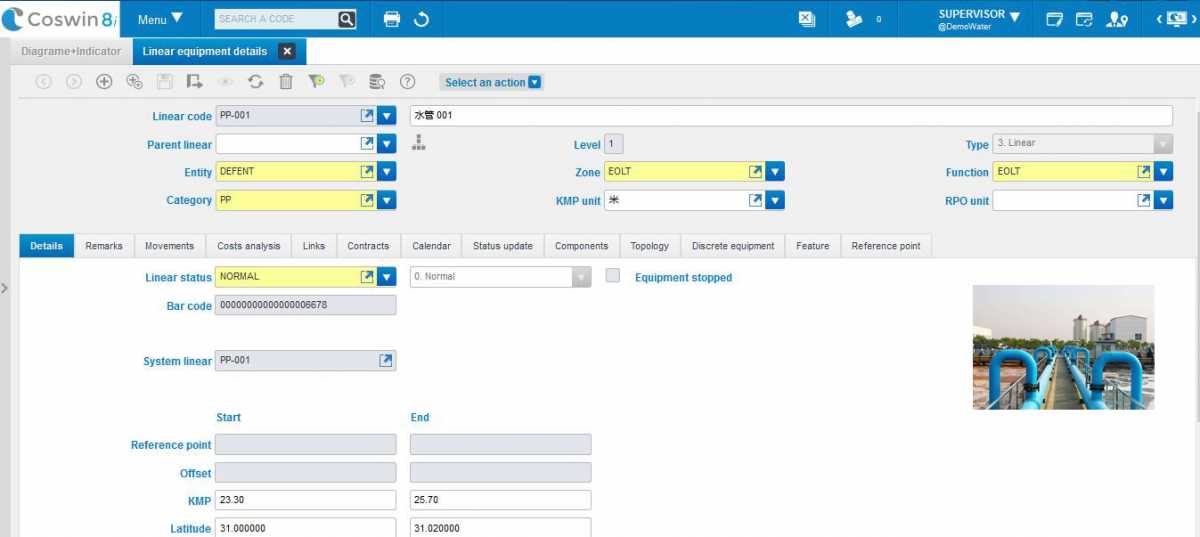

7. Linear assets management

Coswin 8i includes a comprehensive set of features to define and manage linear assets such as pipelines, rails, roads, waterways, power lines… The module, linked to the embedded GIS functions for geopositioning of linear assets on maps, allows specialized teams to plan, report and analyze related maintenance activities.

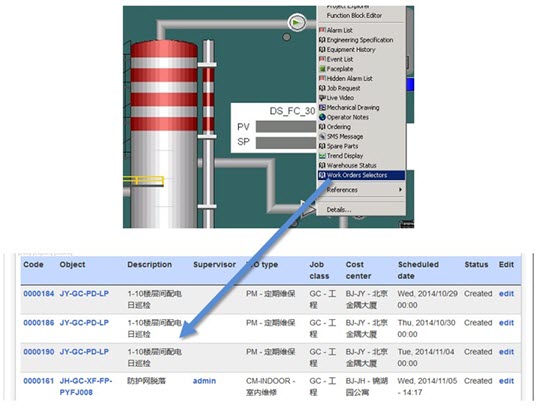

8. User interface integration

Coswin 8i user interface integration module allows authorized third-party software to open specific Coswin 8i screens by calling up a URL with parameters such as equipment tag or work order number. This enables for example a SCADA operator to click on an object in its SCADA HMI to view detailed technical information (from Coswin) in a pop-up window or embedded html page. User rights and security apply. This powerful yet easy-to-use feature opens almost endless integration possibilities.

Siveco China’s R&D center has more particularly been at the forefront of Siveco’s GIS, BIM, IoT and UI integration work, with dedicated teams working on these topics in Shanghai since 2010. Our team is available may you have any question. Contact us at info@sivecochina.com.