The maintenance assessment: a stepping stone for improvement

Maintenance assessments (sometimes called “audit” although we prefer the term “assessment”) represent a growing part of our business in China. This article will explore the principles, practice and benefits of such assessments.

1. Why an assessment?

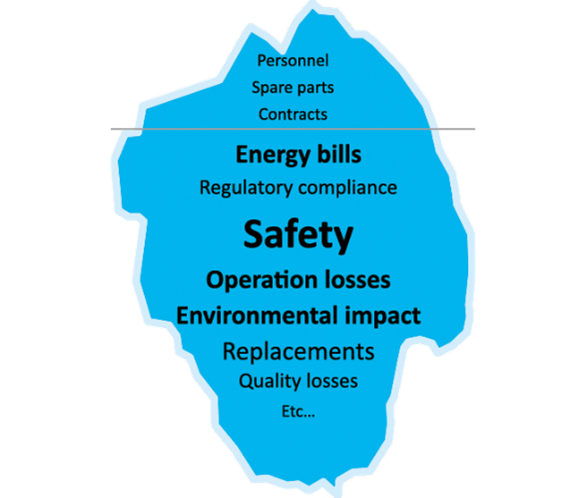

Experience conducting maintenance assessments for over 30 years worldwide has shown that poor maintenance can drag down plant profits by up to 40%. According to benchmarks, even the world’s very best plants can still deliver up to 11% more in bottom line profits.

Yet, maintenance improvement is often not about cutting budgets, but about improving effectiveness, reducing losses and preventing risks: indeed, our studies show that you can save more than 10 times more money by acting on indirect costs and losses, i.e. the impact of maintenance on the business. But: where and how? This is the question we can answer.

The Chinese market, in which our team has been active for over 20 years, presents its specificities. Its modern-time industrial development has long prioritized new construction, capacity expansion, rather than maintenance: the entire supply chain, including design institutes, contractors, equipment suppliers, service companies, the education system etc. was aligned accordingly. In the past few years, official studies have shown that most industrial accidents, safety and environmental problems were caused by technical management mistakes at either working level or top management. Similarly, authorities have identified higher lifecycle cost, in particular due to fast aging (early replacement) or equipment, in public facilities. This has prompted the Chinese government to increase regulatory pressure, a phenomenon that all companies operating in China have observed, and to generally promote a more risk-based approach to technical management.

Based on a unique experience combining both industrial maintenance expertise and consulting project in the past 20 years in China, Siveco China has developed a proven maintenance assessment methodology: an approach that has delivered results for many facility owners and operators in China.

The assessments are designed to answer such questions as:

- Where and what are you risks, losses and excess costs?

- How to get more ROI from your existing systems without new investment?

- Identify maintenance improvements and how to deliver them!

The assessment is designed to address the company’s strategy and top concerns, in line with ISO 55000 Asset Management standard, while adopting a very open wide-angle approach to ensure unknown issues can be identifies.

2. The Siveco China assessment

Principles

Our assessments are always tailor-made to each customer’s specific case. We can however distinguish three types of assessments:

- Maintenance organization assessment – focus on the organization and its processes

- Maintenance system assessment – focus on your systems and their utilization

- Condition assessment – focus on the equipment itself and its condition

Often our assessments combine components from all three types above to answer the key questions:

1. Where do you stand?

- What is your situation now?

- Are you on top of your industrial risks?

- What are you getting for each RMB you spend on maintenance?

2. What could you gain?

- What direct costs could easily be cut?

- What would performance improvements deliver to the bottom line?

- What risks can be prevented, controlled or mitigated?

3. How can you achieve your goals?

- We provide prioritized action plans

- A guide for implementing the action plans

- Based on a knowledge-base of best maintenance management practice

Our working approach

Siveco China assessments always involve active cooperation between the customer’s and Siveco China teams, based on the following working principles:

- A dedicated expert on your project

- An on-site action focused on your main requirements, driven by a Siveco China project manager, assisted by maintenance engineers

- A partnership approach of our work: we recommend efficient, long-term solutions, and prepare your teams in a self-working organization

Confidentiality and independence: Siveco China will sign Non-Disclosure Agreements as required by customer, managed under our ISO 9001:2015 quality system.

Safety is non-negotiable: all Siveco China employees will wear the necessary personal protection equipment when working on site.

Note that all Siveco China projects are offered on a fixed price basis for the scope defined in an agreement.

Methodology

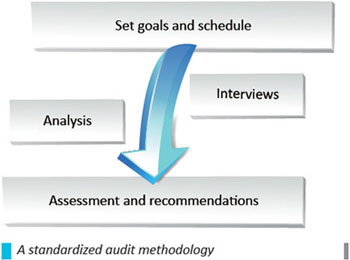

The Siveco China assessments are based on a standard assessment methodology that we have used in many projects across China, and on the professional expertise of our team members, always capable to adapt and improvise if needed.

Whenever applicable, European and IEC standards are used (alternatively, customer can request specific standards to be applied), chiefly the ISO 55000 Asset Management standard (also known as the GB/T 33172-2016 series in China).

Assessments always comprise three main phases as shown in the figure:

For the assessment, standards of interest include:

- ISO 55000 Asset Management – Management Systems, as a risk-based framework for maintenance.

- EN 13460: Maintenance – Documents for maintenance.

- EN 15341: Maintenance – Maintenance key performance indicators, as offering a user-friendly collection of standard performance measures.

- CEN/TR 15628: Qualification of maintenance personnel, for HR/skills management aspects.

- ISO 14224 Collection and exchange of reliability and maintenance data for equipment, addressing data needed to manage maintenance and offering strong support for the design of a maintenance system.

Deliverables

The main deliverables for the assessment are:

- Detailed assessment report (completed Excel document and analysis report, which would include, depending on the scope of assessment, pictures, work processes maps, etc.)

- Recommendation report with related action plan. Recommendation report could include ROI estimates (if financial data was made available to Siveco China) or other improvement metrics.

- Optionally, the above data and action plans in advanced electronic format (for example to be managed in a CMMS) with possible follow-up services by Siveco China.

The report with our recommendations will be presented to the management team at the end of the project, after which discussions will take place. A final conclusion report will be drafted at the end of the session.

3. The supporting tools and resources

Benchmarking

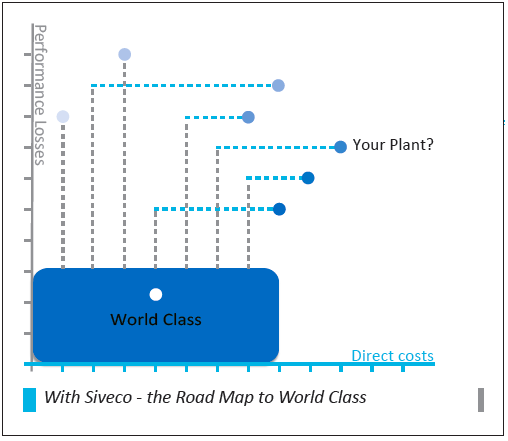

Benchmarking with international standards and other companies plays an important role in all Siveco China assessments.

Our growing customers’ database in China and abroad allows us to benchmark your operations to other plants in similar or different industries. We also run multisite assessments with internal benchmarking between your own sites.

A strong basis for our maintenance benchmarking in China has been the annual “Maintenance in China” survey that Siveco China has run in association with the Sino-European School of Technology of Shanghai University and the European Chambers of Commerce since 2006, covering over 1,500 multinationals in the country.

IT tools

Owing to Siveco China’s strong background in using technology to support maintenance improvement, IT tools play an important part in supporting assessment services, depending on the scope and size of the assessments.

The three main IT tools used by Siveco China to manage all its projects are:

- 8Manage: for project management

- bluehoney: for project activity time and cost reporting

- Ding Talk: for travel approvals and internal chat communication

In addition, detailed methodology guidelines for each types of assessment is pre-established, serving as a guide for Siveco China’s engineers during the assessment itself, in Excel and/or document formats, centralized in Siveco China’s cloud server.

Finally, when conducting site assessments, Siveco China engineers are equipped with bluebee® Surveyor: a unique tool to capture information from the field, record asset conditions, or even to build a complete facility or plant database by simply walking around and taking pictures. Follow-up actions (job request, preventive job) are automatically created and updated into Siveco China’s central server database. Depending on the scope of contract, Siveco China can then deliver a complete technical database, including photos, remedial actions to be taken, etc. in CMMS format (by remote access or installed at the customer’s site).

All our management systems are web based or mobile based, allowing access from anywhere.

The Siveco China back-office

Assessments are conducted by true maintenance experts appointed on the project, under the responsibility of a dedicated project manager:

- Our team members have worked previously as maintenance managers, preventive maintenance engineers, CMMS leaders in facilities, manufacturing and infrastructure projects.

- The Siveco China team comprises both local experts and foreign experts with experience of world-class maintenance.

- Our CMMS experts have working knowledge of various systems (CMMS, ERP, SCADA) available in the Chinese market.

In addition, during the entire project, the assessment team will have access to Siveco China Shanghai’s back-office resources, which includes:

- Back-office teams and the Siveco China network of experts on specific technologies (e.g. vibration analysis or corrosion), specific facilities or equipment (e.g. HVAC specialists) or methodologies (e.g. IEC standards).

- Centralized IT tools including benchmarking database and CMMS.

4. The assessment and its benefits in practice

In practice, for the typical assessment, two Siveco China engineers will come to your site for approximately one week. For a CMMS/EAM assessment, one engineer will focus on maintenance management, the other on the utilization of the system itself. For a more organizational assessment or a facility condition assessment, the assessment will involve specific industrial skills as required. Onsite work will be concluded by a presentation workshop, followed by report preparation time, before the final deliverables are handed over to the client.

Siveco China has experience conducting assessments in all three target segments: Facility Management (property owners and FM suppliers), Industry (factories in various industry, process or discrete manufacturing) and Infrastructures. Nowadays, in addition to independent assessments, all our projects include a start-up assessment and our “enhanced maintenance contracts” also utilize our assessment practice. The accumulated experience of our team (some of our team members have been active in this field since 1997) is unparalleled in China.

A case study of a CMMS assessment was presented in a past newsletter.

Some of the concrete benefits observed in previous assessments include:

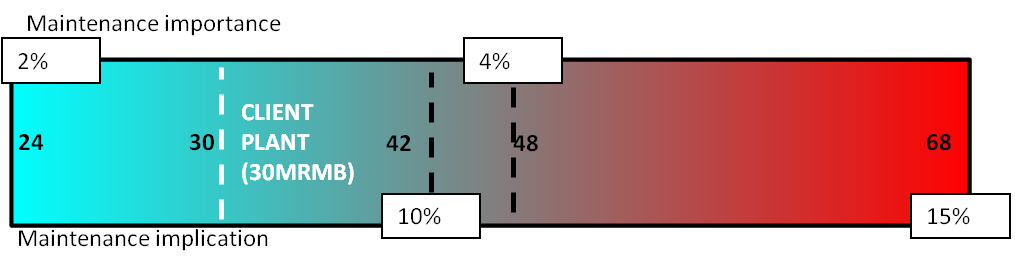

Maintenance organization assessment at a large process plant

The overall conclusion of the assessment showed that the company should focus on improving performance instead of further cost cutting: analysis of financial figures and comparison with benchmarks show that the plant has extra capacity to fund this effort, i.e. it can easily afford the additional cost. This would result in downtime reduction with easily measurable returns: a detailed technical study estimated returns at 1 million RMB within one year on the main machines alone.

Benchmarking of key metric (figures are in millions RMB).

CMMS assessment (SAP PM and various other systems) at a chemical plant

The in-depth assessment showed that the company underutilizes its SAP infrastructure but has built a practical way to work around it, using various additional systems and well-defined management procedures. Overall the maintenance system is working rather well compared to similar companies in China, whether using SAP or other CMMS tools. This is to the credit of the company’s strong maintenance team members and management.

Weaknesses in analysis and decision support started to affect the capability of the maintenance division to improve its performance, while production put increasing demands on reliability.

Siveco China recommended implementing small improvements in SAP Work Orders and to develop better reports (probably using the SAP Business Warehouse tool already in place in other departments). A third-party mobile solution would certainly enhance the inspection process, allowing a full feedback loop to manage preventive maintenance improvement. The costs/benefits of the various options were analysed.

CMMS assessment (Maximo) at automotive plant

The assessment found that the maintenance organization focuses its efforts on basic preventive maintenance: inspection, greasing, etc… as it lacks the necessary tools to eliminate failure through technical analysis. As the maintenance team is understaffed and busy with production-related tasks, and without proper support from the CMMS, they do not have the time to manually process long lists of WO feedbacks, although they do have the technical knowledge to understand their machines and find solutions.

This situation finally leads them to insure themselves against breakdown risk by adding more inspections (i.e. more workload). This is consistent with the pure “workstation approach” of the current failure analysis tool: the inspection plan is based on workstation.

The systems proved to be one of the bottlenecks and no solution was proposed by the IT vendor other that providing resources to develop reports. These problems reflect implementation- rather than software-related weaknesses, resulting in low ROI on the CMMS investment.

Siveco China recommended a complete course of action, based on improving technical feedback, with standard pick-lists for downtime, causes, actions etc. The equipment structures should be reorganised to accommodate such reporting (currently not possible). IEC 81346 or ISO 14224 standards were proposed as the basis for this change.

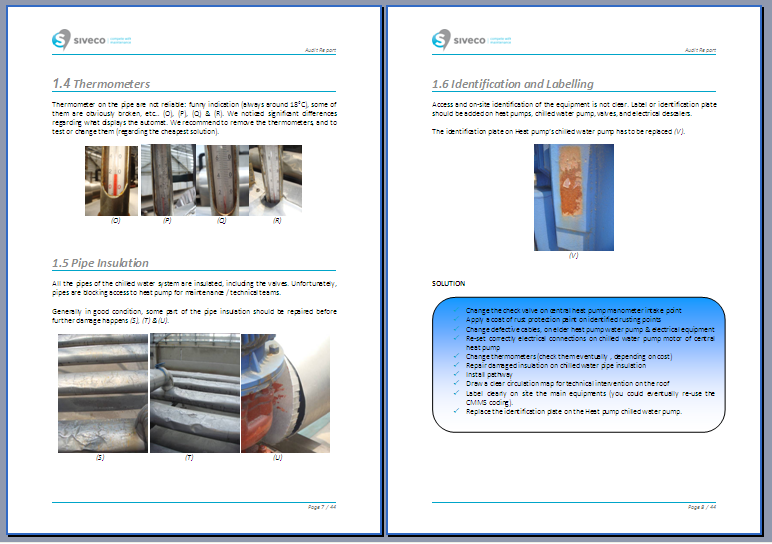

Facility condition assessment at a major retailer

A full facility assessment was conducted in one of the buildings, covering the building itself and all systems (HVAC, water, fire-fighting, lifts, etc). The study also included a review of the FM suppliers’ contracts, the quality of their work and the paper-based reporting systems. Siveco China delivered a full assessment report in two formats: office documents (word file with pictures, Excel list of recommended actions, updated maintenance plan in Ms Project format) and in database format, easily up-loadable into a CMMS. For each problem detected, a diagnosis was proposed, together with corrective and future preventive actions, allowing the retailer not only to take immediate measures, but also to prevent reoccurrence of problems. A management solution was proposed in order for the customer to better manage its facilities in the long term.

Sample facilities assessment report (also delivered in Excel and CMMS database format)