Data preparation for SAP PM (and other CMMS)

The specialists data preparation services for SAP PM (or other CMMS) provided by Siveco primarily target greenfield projects. In some cases, such services may also apply to existing plants.

Background

With a strong background in greenfield infrastructure and industrial projects, Siveco has developed a specific expertise working alongside investors, EPC companies and their equipment suppliers during the construction phase, ensuring smooth transfer of technical documentation from construction to operation.

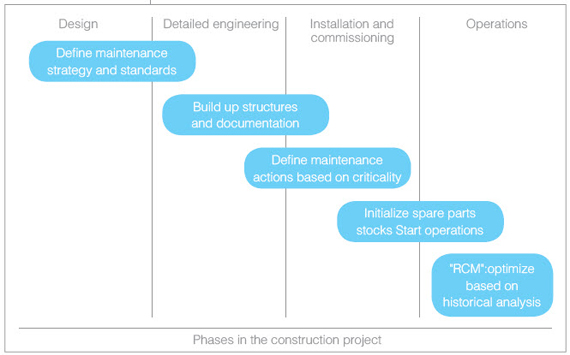

The figure summarizes the Siveco approach for maintenance preparation during a construction project.

Scope of data preparation

Data preparation is a key aspect of SAP PM projects (and more generally of any CMMS project), which will have a major impact on the usage and usefulness of the system for years or decades afterwards. A need unattended by traditional SAP implementation consultants and IT firms, which lack the necessary maintenance know-how, it is usually left to the customer’s teams, who are requested to fill in complex Excel templates, on top of their existing operational responsibilities, with a limited understanding of how this task will affect their future use of the system.

Data preparation covers the establishment of the plant functional locations and equipment structures, with all related information: criticality, specifications, documentation, as well as spare parts, warranty periods, contracts, preventive maintenance instructions, etc.

Siveco’s working approach consists in working with the plant owner and their EPC company, ideally at the very early stage of the project to ensures that the obligation to provide technical data in the predefined format (templates) is part of every equipment supplier contract, with a clear delivery schedule. By doing so, each supplier is ultimately responsible for the quality of the data provided, include re-work if needed. The entire data preparation process is managed by Siveco experts, with an intimate knowledge of both plant maintenance operations and SAP PM and other leading CMMS. Siveco will advise on coding systems based on EPC or plant owner’s requirements and international standards (e.g. KKS or IEC 61346).

Alternatively – and more often than not! – when the EPC and equipment suppliers cannot play their role of data providers, Siveco will take full responsibility for the entire data build-up, in “full turnkey” model. Siveco engineers work from P&IDs and equipment, instruments, lines list to build functional locations and equipment structures in the specified SAP format. Spare parts lists (with delivered quantities and planned quantities for the first maintenance cycle) and preventive maintenance instructions, linked to relevant equipment, are created from O&M manuals or, in some case, by Siveco’s own engineering know-how, relying on industry-specific partners when needed. Technical documentation and drawings are in the same manner linked to relevant SAP PM objects. Master data can also be created by Siveco.

The list below summarizes the main data types that Siveco can help prepare:

– Functional locations structure and equipment data

– Spare part lists, linked to corresponding equipment

– Documents, linked to corresponding equipment

– Maintenance instructions (preventive or standard corrective instructions)

– Master data (including generic fault types applicable to all equipment)

– Spare part lists, linked to corresponding equipment

– Documents, linked to corresponding equipment

– Maintenance instructions (preventive or standard corrective instructions)

– Master data (including generic fault types applicable to all equipment)

Siveco will ensure the as-built technical accuracy of all data supplied and deliver the data is the format specified by customer, usually Excel templates ready for import to SAP PM. The actual data upload, a simple IT job, is not under Siveco’s responsibility.

Resources and tools

Most of the work is carried out at the two Siveco engineering back-offices in Shanghai and Chengdu, under the supervision of a project management team in direct contact with client, via regular face-to-face meetings. For very large resource-intensive jobs, certified Siveco partners may involve.

A strong methodological framework is offered through international standards (e.g. IEC 81346, EN 15341, EN 13269, PAS 55, ISO 14224) and technological tools (mobile and back-office systems) used by Siveco service teams.

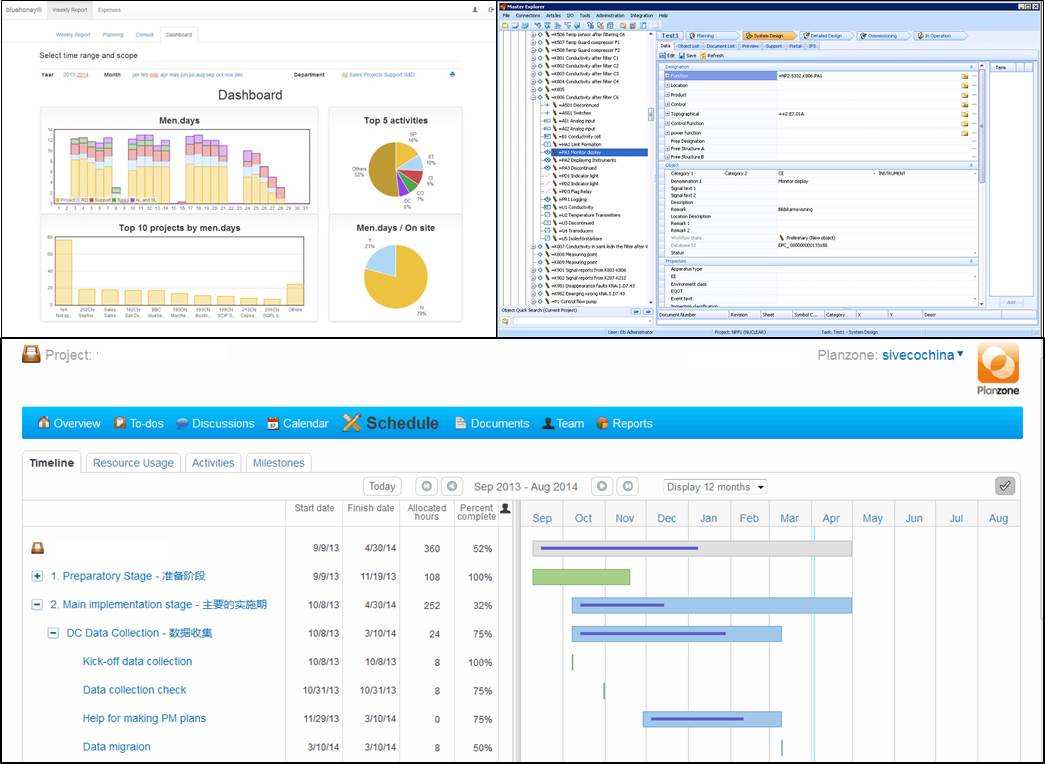

Siveco uses specialist IT tools to ensure quality, accuracy and efficiency of the data preparation work. The tools used at Siveco office include Ides Master Concept to manage data templates, coding rules, plant structures with attached documents and multiple data revisions from design to as-built. Master Concept also allows exporting to various Excel and xml format. Other tools used are the Siveco bluehoney® back-office system, with the integrated Plazone project management platform and time reporting. For existing plants and on-site data collection (also useful for onsite confirmation of as-built data during commissioning), Siveco engineers use bluebee® surveyor.

References

The Siveco China team has extensive experience of data preparation services, mainly in power plants (gas turbine, coal, hydro and nuclear), chemical plants and pulp & paper. Contact us for more details.