Implementing a CMMS during plant construction

Introduction

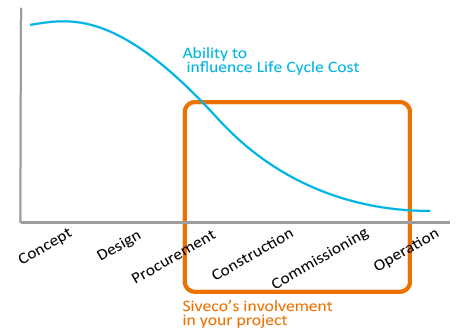

Experience has shown that the earlier reliability and maintainability are taken into account in a construction project, the better. These should be specifically addressed from the design stage of a project, as illustrated below.

This approach, which consists in paying more attention to maintenance earlier in the project, to reduce future operation cost, differs markedly from that of most Asian engineering and construction companies, which emphasize cost control during construction with progressive adjustments and modifications of the design as the project moves ahead. Too often EPC companies still lack an overall lifecycle perspective, hence the difficulty to obtain as-built drawings or preventive maintenance recommendation from them.

While the resulting speed and cost advantage has proven critical to support those countries’ fast development, this construction-driven approach has also led to problems – most notably in terms of safety (accidents at construction sites) and maintenance (early replacement of major equipment, spiraling cost and reliability problems after a few years of operation). Partly as a result of this lack of preparation, maintenance is often purely reactive (firefighting) in the operation phase.

As a direct consequence of this lack of early concern for maintenance during construction, we observe that the quickest reliability improvements obtained during Siveco project in the region are those related to design or installation problems, which should have been identified during commissioning, but instead go undetected for years. Quick fixes are applied, problems go unreported and no analysis is ever carried out. By conducting systematic root cause analysis, we are able to identify the problems and trace them back to construction issues.

The Siveco approach

Based on a long experience of greenfield projects all over the world, primarily with process plants (chemical plants, power and water utilities, paper mills) and lessons learnt in China in the past 10 years, Siveco has developed a specific expertise working with plant owners and/or their EPC companies and equipment suppliers during the construction phase, ensuring smooth transfer of technical documentation from construction to operation, supporting plant commissioning and start-up with an accurate technical database and enforcing good maintenance practice from day one.

In Asia more than anywhere else, the CMMS turns out to be the ideal tool to bring structure to what would otherwise be perceived as a very abstract concept (“Prepare for maintenance? But the equipment has not yet been delivered!”). A concrete (deliverable) system, the CMMS allows us to clearly define steps in the maintenance preparation project. The “high-tech factor” introduced by the CMMS is of course a key motivator for engineers involved in the project.

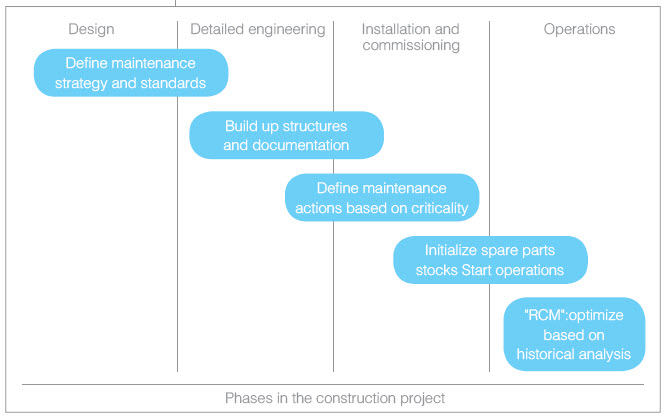

The figure below summarizes the Siveco approach for maintenance preparation during a construction project based on the utilization of the CMMS:

Main benefits

Detailed, accurate and easily accessible plant documentation

By working directly with suppliers, detailed and accurate technical documentation (specifications, contracts, spare-parts lists, etc.) can be made available to operation engineers in a structured manner directly in the CMMS, instead of being stored in containers, in shelves or even missing. This has a direct and immediate impact on the accuracy and efficiency of the work as well as on day-to-day decisions (where to purchase a part, how to disconnect an equipment etc.).

Integration with automation systems

The construction phase is obviously the best time to integrate the CMMS with automation and supervision systems (DCS, SCADA, PLC etc.) that contain essential data for maintenance planning, as both systems can be designed and build accordingly. Large cost savings can be expected compared to similar integration performed in operation (with an existing supervision system).

More importantly, more advanced functionality can be obtained, such as a full HMI integration (operators can access technical documentation directly from their supervision HMI) and more meaningful data transfer (e.g. traditional interfaces will transfer alarms and measurements to the CMMS indiscriminately, while in a joint implementation, the process will be designed to match the maintenance strategy).

Siveco boasts a long history of cooperation with leading automation vendors in various industries (ABB, Alstom, Siemens, Schneider, Emerson, GE etc.).

Optimized plant lifecycle

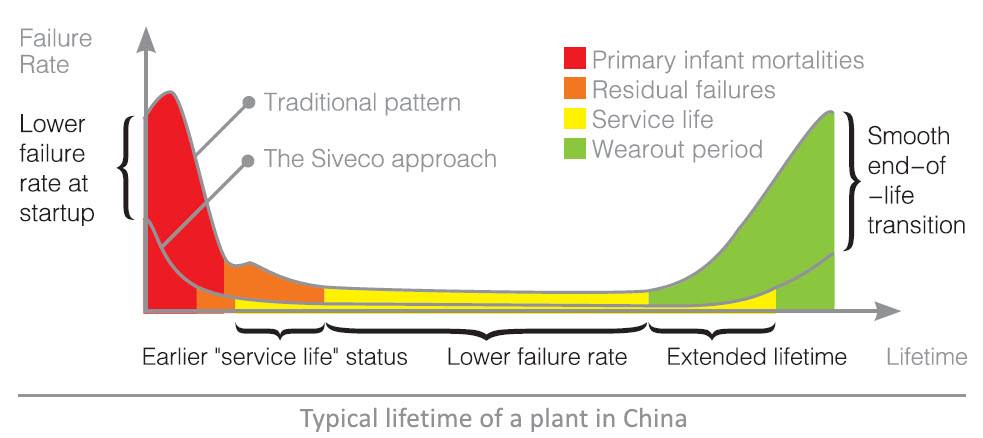

For large process plants, this approach could easily save millions of dollars in indirect or consequential losses: downtime, increased repair costs, recurring problems etc. By taking maintenance into account early, it takes less time to get into the “useful lifetime” part of the famous reliability “bath-tub” curve (below), while the “wearing out” part will be delayed.