Flipping the script on Industry 4.0: why 61% of projects fail and how to fix it

Industry 4.0, integrating smart technologies like IoT, AI, and automation into industrial operations, promises transformation but often falls short. McKinsey reports that 61% of Industry 4.0 projects fail due to lack of process focus, employee engagement, and continuous improvement. For maintenance systems, the failure rate may be closer to 90%, a staggering figure. How often have you heard an IT project failed because the team was “not mature enough” or management was not engaged enough? Probably 61% of the time, right? This massive failure rate is unacceptable from an industrial perspective. Yet it often leads to hiring consultants who offer generic recommendations, recycling familiar excuses and shifting blame to end-users. while the real issue lies in flawed project approaches.

An insidious side effect is that some firms, particularly multinationals in Asia, postpone modernizing their operations, ending up lagging years behind more aggressive technology adopters.

At Siveco China and Bluebee Technologies, we believe this approach is upside down. Organizational maturity is not a prerequisite: it is the goal of the project.

An upside-down approach

Industry 4.0 projects often fail because they assume maturity rather than foster it. Without user-friendly tools, shop floor workers remain disengaged. Without continuous improvement, systems stagnate. Without management buy-in, projects lose momentum. Our Smart O&M solution flips this mindset. The bluebee® system, its implementation, and long-term support services are designed to build readiness from the ground up, structuring teams around clear processes, training them on modern methodologies, and guiding stakeholders at every step, from shop floor inspections to boardroom decision-making.

Solution design: bluebee® “for the worker of tomorrow”

Since its first release in 2008, bluebee® has put people – not technology or machines – at the center. By systematically recording incidents, inspections, and work, bluebee® creates a technical knowledge base to support teams, ensure compliance, and inform management decisions. Designed for technicians, it replaces manual input with scanning, photos, value selection, and automatic time/location capture for accuracy and ease of use. bluebee® motivates workers, trains them on-the-job, organizes them around clear processes, and gently enforces best practices from top managers to shop floor teams.

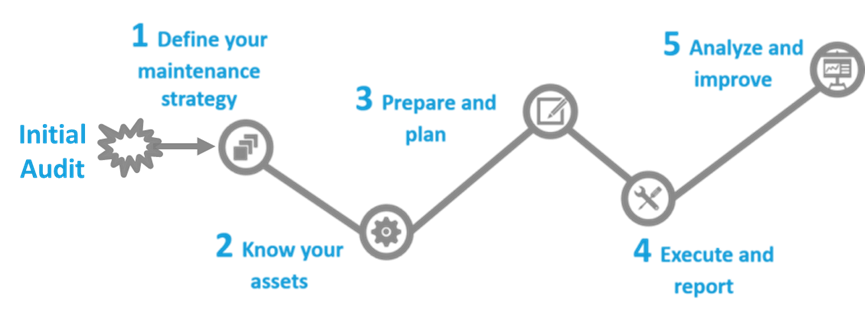

Implementation: an ISO 55000 driven approach

Unlike vendors who treat software as the end goal, our Smart O&M specialists view it as a tool to achieve management objectives, define maintenance strategies, and drive continuous improvement. The ISO 55000 Asset Management standards provide a practical, risk-based framework for IT projects in asset-intensive industries. By prioritizing industrial needs over feature lists, ISO 55000 helps overcome typical obstacles and ensures alignment with business goals.

Support services: enhanced maintenance support

Our “Enhanced Maintenance Support” contracts go beyond traditional software support and fixing bugs. They guarantee measurable improvements in system utilization. Our experts conduct annual site assessments, provide tailored recommendations, remotely monitor progress and coach the client team. At year-end, we jointly evaluate results and plan the next steps, ensuring sustained success.

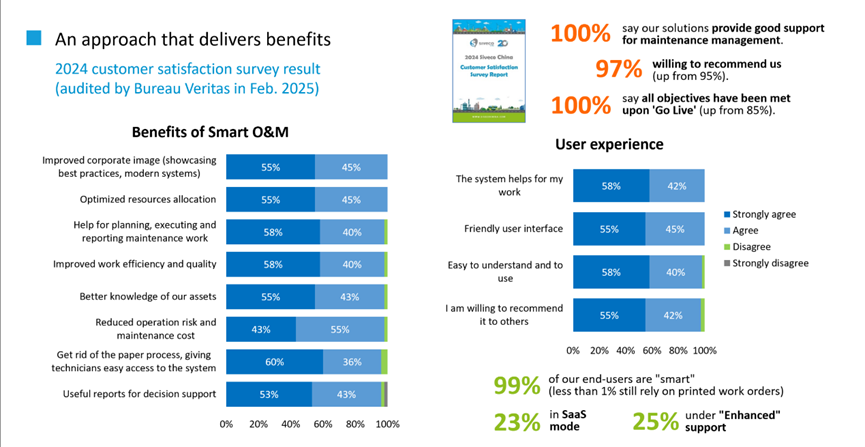

Proven results

Our 2024 customer satisfaction survey highlights the impact of this approach.

To name a few clients our teams have been following for years: Daramic, a global manufacturer of battery separators, transformed its Asian plants into a model for the group. Chonburi Clean Energy, a waste-to-energy plant in Thailand, became a global top performer in Veolia globally. Casda Biomaterials in China, formerly part of Arkema, earned industry accolades for its digital transformation.

While too many industrial companies face repeated project failures or delay improvements waiting for a “mature” team, our approach solves this chicken-and-egg problem. It’s not just software: it’s a framework to transform how teams work, from the shop floor to the boardroom.

Ready to get your house in order? Contact us info@sivecochina.com to learn how Smart O&M can drive your success.