2017 Maintenance in China survey: does maintenance play a role in the China Dream?

Introduction

Launched in 2008 and now in its 5th edition, the “Maintenance in China” survey is a joint project between the Sino-European School of Technology of Shanghai University (UTSEUS) and Siveco China, the country’s largest maintenance consultancy. It is by far the most comprehensive survey of its kind.

A benchmarking opportunity for companies operating industrial assets in China, this year’s survey also offers interesting insights in the changing role of maintenance, long underestimated, as the country enters a new phase of its industrial development, moving up in the value chain, with increasing automation, robotization and focus on sustainable development, embodied in such concepts as the China Dream and Made in China 2025.

The questionnaire

The questionnaire was aligned with the ISO 55000:2014 family of Asset Management standards, now also available as Chinese standard GB/T33172-2016 (approved by the Standard Administration of the People’s Republic of China (SAC) on October 13, 2016, effective from May 1, 2017 under the names: GB/T 33172-2016资产管理, 综述、原则和术语,GB/T 33173-2016资产管理, 管理体系 要求, GB/T 33174-2016资产管理, 管理体系 GB/T 33173应用指南).

Questions covered:

•

Maintenance strategy & business impact

•

Execution and supporting tools (staffing, training, preventive maintenance, relations with production, spare parts, subcontracting, documentation, IT tools)

•

Decision support & improvement

Respondents

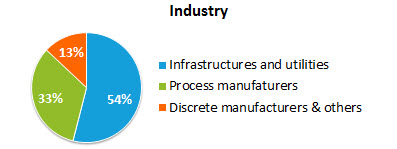

The 2017 survey received 493 responses, from 453 different companies, with sites located all over China.

The survey was dominated by Chinese companies and joint-ventures, unlike previous editions (84% multinationals in 2013). Most local respondents are infrastructures & utilities, most international companies are manufacturers.

Executive summary

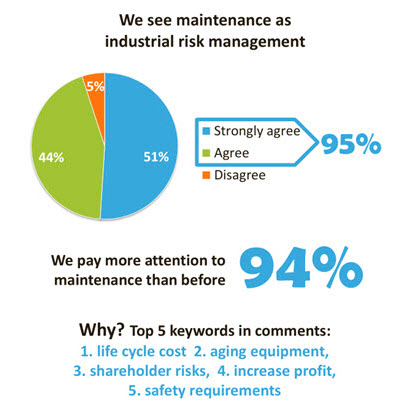

Responses show great awareness of maintenance, more particularly among Chinese infrastructures and utilities, with risk prevention as a key driver.

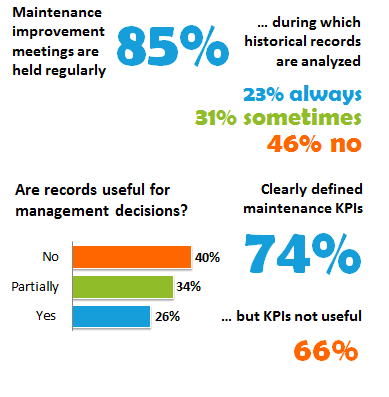

Execution however is still lagging: decision support is a weak area, making it difficult to close the “feedback loop” as per the ISO 55000 (or GB/T 33172) Asset Management standard.

When maintenance management controls and tools have been put in place, they seldom produce the expected results in terms of decision support. For example:

Most companies are considering improvement actions that could help address those concerns.

Conclusion

The survey shows that best performers:

•

Have a maintenance strategy

•

See maintenance as risk prevention

•

Have a CMMS (81% of local respondents do not)

•

Hold regular meetings…

•

… during which historical records are analyzed

For more in-depth analysis

All respondents have received a copy of the full report in English and Chinese. The full report also explores preventive maintenance, spare parts management (shown to be a particularly weak area), technical documentation, IT systems, training, staffing, etc. Upcoming Reliability articles will also provide in-depth analysis of these findings.

To request a copy of the full report, please email us at info@sivecochina.com with your full contact details.

We would like to thank all the respondents!