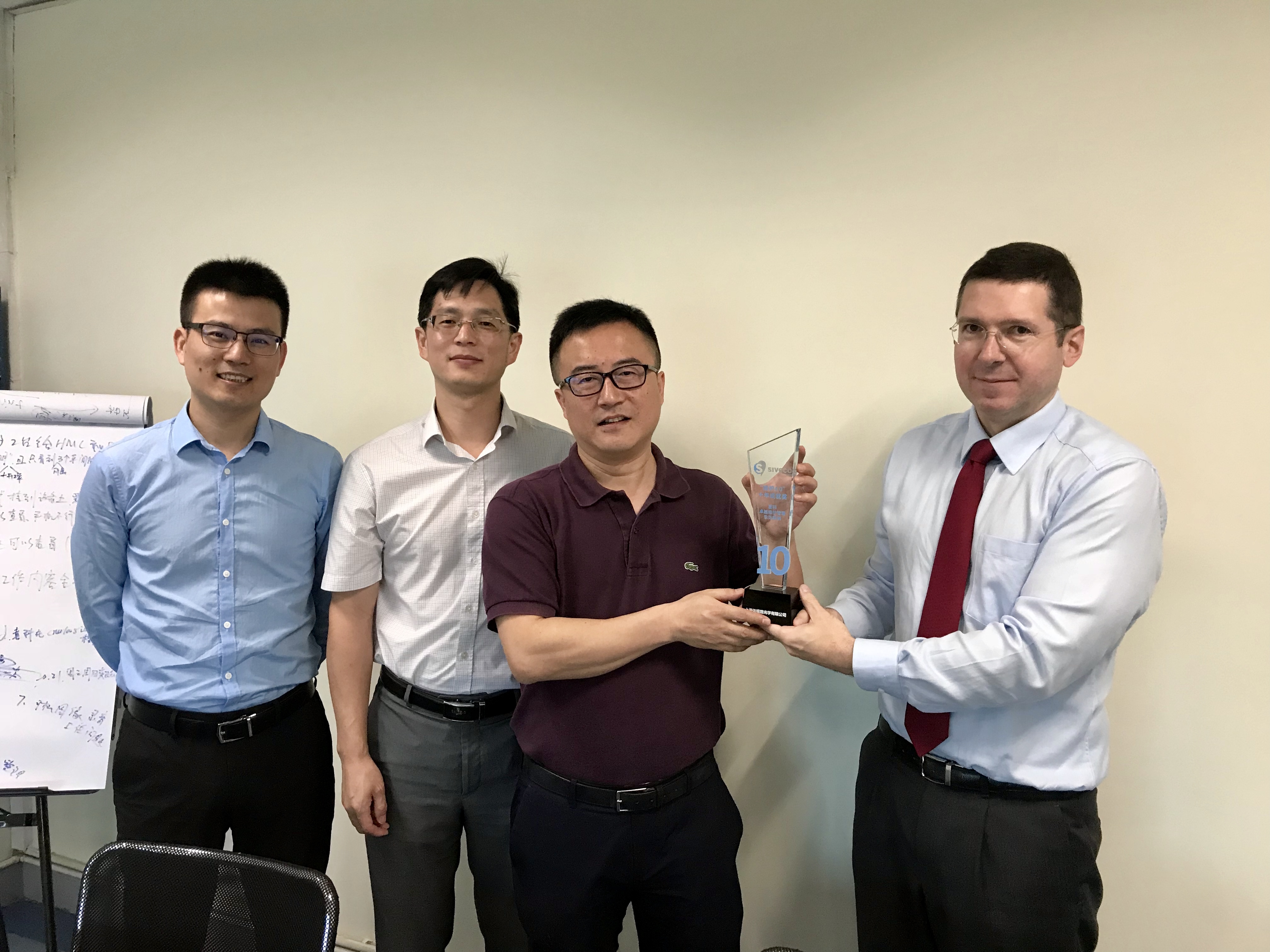

Essilor Shanghai receives “Ten Years Achievement in Maintenance 4.0” award

On June 21, Shanghai Essilor Optical Company (SEOCL) received the “Ten Years Achievement in Maintenance 4.0 – Showcase of Maintenance Management Excellence” award, recognizing the consistent improvements achieved over the years using Siveco solutions.

Essilor, the world’s largest manufacturer of ophthalmic lenses, first installed Coswin 7i in the Shanghai factory in 2008. Based on this first successful experience, the company subsequently extended Coswin usage to factories in Brazil, Laos and Thailand. SEOCL is now using Coswin 8i and bluebee® in both its mass production plant and its prescription lab (the world’s largest) located in Songjiang, Shanghai. Unlike most multinationals, Essilor actually initiated its Maintenance 4.0 project in China, before expanding it elsewhere. This approach parallels that of Siveco China, developing from China to the “Belt & Road”.

A case study of Essilor Shanghai consistent maintenance improvement was published in 2011 in the “Maintenance in China” newsletter and this experience has been featured at several maintenance and reliability conferences over the years, proving the validity of Siveco’s business model that combines maintenance consulting and Maintenance 4.0 technologies.

During the recent ISO 9001:2015 audit of Siveco China by Bureau Veritas, the auditing team spent half-a-day on site at Essilor Shanghai to review Siveco’s project delivery practices: both Siveco and Essilor received praise from auditors.

The entire Siveco team thanks the SEOCL team for their friendly and efficient cooperation over the past decade, a fruitful relationship which now continues in its second decade in China, Asia and the world.