Cross-department cooperation at its best: Smart O&M (CMMS) implementation at Hebei CASDA Biomaterials

About Hebei CASDA Biomaterials

Hebei CASDA Biomaterials (CASDA) is a global leading manufacturer of sebacic acid. CASDA specializes in sebacic acid, dimethyl sebacate (DMS) and dibutyl sebacate (DBS) products. A number of industries have benefited from its contributions, including aerospace, automotive, electronic products, consumer goods and sport.

Project Background: The Start of Digital Transformation

Driven by the wave of digitalization, Hebei CASDA Biomaterials Co., Ltd. has been exploring how to improve the systematization, standardization and digitalization of its maintenance management by introducing a computerized maintenance management system (CMMS) since 2016. This strategic decision is aimed at responding to improve equipment reliability and optimize resource costs. Siveco China was selected for the project in September 2021 through a comprehensive competitive evaluation.

Project implementation: a model of cross-departmental collaboration

In 2021, CASDA’s management team, under the active promotion of the business unit and the maintenance department of the headquarters, decided to launch the CMMS project. Starting from scratch, the project team carefully studied and understood CASDA’s core modules and management processes of maintenance management. During the three-year pandemic, in the face of various challenges, the Engineering Maintenance Department, Finance Department, IT Department, Production Department, Procurement Department, HSEQ Department and Technology Department and other departments demonstrated excellent teamwork spirit and jointly promoted the implementation of the CMMS project.

After the project was launched, the joint project team of CASDA and Siveco China conducted in-depth communication and research, and developed a customized model suitable for CASDA. This model defined the Excel template for data collection, relevant business processes and management KPIs, laying a solid foundation for the smooth implementation of the project.

On January 1, 2023, the official commissioning of the maintenance module marked the successful completion of the first phase of the project and opened a new chapter in the improvement of engineering maintenance management. Subsequently, the project team realized the visualization and digitalization of Capex project management in April, further expanding the functions of the CMMS system under Siveco China’s Smart O&M framework.

Project benefits: Comprehensively improved maintenance management

Through the implementation of the CMMS system, CASDA has achieved remarkable results in many aspects. First, a plant-wide equipment technology database was established to provide standardized data support for equipment performance indicators and cost analysis. Secondly, through process standardization, personnel work efficiency is improved, and fault analysis is strengthened through SDCA (Symptom, Defect, Cause, Action) analysis.

The introduction of mobile inspection solutions makes on-site inspection work more efficiently and ensures the authenticity, traceability and analysis capabilities of inspection data by enforcing systematic recording of failures, inspections and work done.

In addition, the CMMS project has been expanded to finance, safety, production and other departments, improving the overall information management level and formulating standard processes for Capex project management and MOC (Management of Change). This demonstrated the value of the Smart O&M platform of Siveco China, wider and deeper than traditional CMMS.

The establishment of spare parts management and procurement management processes and the connection with the financial system not only reduced costs, but also improved the efficiency of the maintenance team. The optimization of the reporting system reduced the time for manual statistical reports, improved the accuracy of the reports, and provided strong support for the continuous improvement of internal management.

Monthly spare parts consumption cost

Continuous improvement: continuously optimizing management practices

During the project implementation, CASDA continuously collected and improved basic data, laying the foundation for standardized management. The development and integration of maintenance and procurement management modules not only conforms to the core maintenance management model, but also adapts to the company’s current situation.

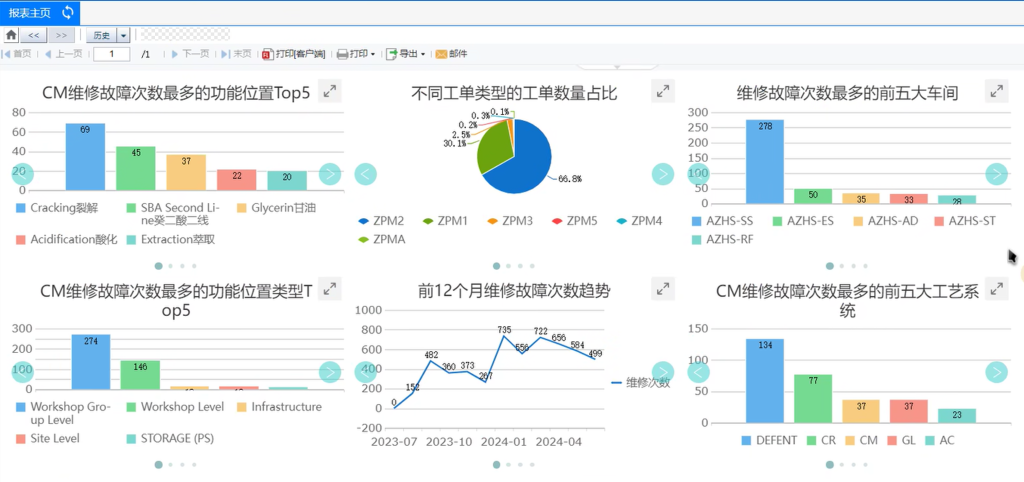

The development of Capex and MOC management modules meets management needs in a simple way and provides full life cycle management support. The interface development between the CMMS and the financial system realizes the automatic system integration of Chinese factories. The development of 84 maintenance system reports ensures that the system operates in a visual and digital way, covering multiple dimensions such as asset management, work order management, and procurement management.

The CMMS project team won the “Outstanding Team of 2023” award for this project. The case study of Hebei CASDA is not only a successful digital transformation practice, but also a model of cross-departmental collaboration, continuous improvement and innovative management. Through this series of efforts, the company not only improved the efficiency and quality of maintenance management, but also laid a solid foundation for the company’s long-term development and competitiveness.