How Smart O&M assists the wastewater division of Jiangsu Sino French Water in the implementation of O&M best practices

In this project, the wastewater company adopted the latest technology of Siveco’s Smart O&M solutions including the mobile app for maintenance management. All technical data, work orders, work instructions and reports, etc. are stored in the back-office system. The system generates work tasks or work orders from predefined strategy, plans and frequencies. The work orders will be displayed on the user’s PC dashboard, according to the specified date, which is very intuitive.

read moreSiveco clients share experience at the 2020 customer event in Kunshan

On November 13, Siveco hosted clients at the site of customer Smart Factory Kunshan (Jiangsu province) for its 2020 customer sharing event.

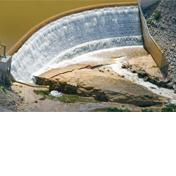

read moreOn the Belt & Road: Q&A with Brazilian hydropower company PCH

In 2019, State Grid Brazil Holding selected Siveco to implement its maintenance management solution across a dozen subsidiaries and majority-owned concessions. Created in 2007, three years after Siveco China, in Rio de Janeiro, Siveco Brazil provides sales, consulting, installation, training and technical support for customers locally. Siveco solutions are fully localized for the Brazilian market. Siveco Brazil and China have enjoyed, for many years, a close cooperation targeting global manufacturing groups and public infrastructures.

read moreOil storage achieves continuous maintenance improvement with Siveco

The Smart O&M project implemented by Siveco for Nangang petroleum storage has entered its fifth year of operation. Making full use of the maintenance management system put in place before startup, the maintenance team of Nangang terminal insists on the maintenance summary meeting at the end of each month and analyzes the work situation of the month by using the standard report defined by Siveco. Multiple data indicators, including: work order completion ratio, top five failure causes, and top five repair measures, etc. have become the main reference for reviewing the maintenance team work, and it has truly helped Nangang team to continuously improve maintenance...

read moreSemiconductor gas producer controls plant maintenance risks with bluebee®

After several rounds of evaluation and reviewing Siveco’s successful references with other industrial gas plants in China, YTNS selected Siveco to implement its innovative bluebee® solution, with consulting services aimed at tackling the challenges already identified. To achieve the project objectives, Siveco proposed a coordinated five-step methodology based on the ISO 55000 Asset Management standard.

read morePredictive maintenance, in line with Industry 4.0

The new maintenance model developed by Leonardo at its Cisterna di Latina site (near Rome, Italy), in partnership with its supplier Siveco, led to a breakthrough in efficiency, reducing downtime and improving sustainability at the site. We discussed the predictive maintenance project, which Leonardo recently developed with Siveco, and looked in-depth at the excellent results generated and how the project is now being rolled out to other Leonardo sites.

read more