Cost savings with bluebee®

In this month’s reliability article, we take our readers through the benefits of using bluebee®, as shown in the bluebee® movie.

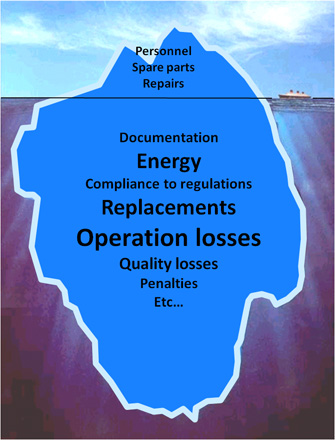

At Siveco, we often remind our customers that indirect savings from maintenance improvement matter more than direct savings, especially in our home market of China, where the direct cost of maintenance tends to be low.

This is best shown in the form of an iceberg:

The bluebee® movie, however, seems to focus on time savings, i.e. on direct labor cost. Here is why.

Time savings

Studies show that up to 70% of technicians working time is spent on administrative tasks, looking for information, tools, manuals, drawings, parts, other people…

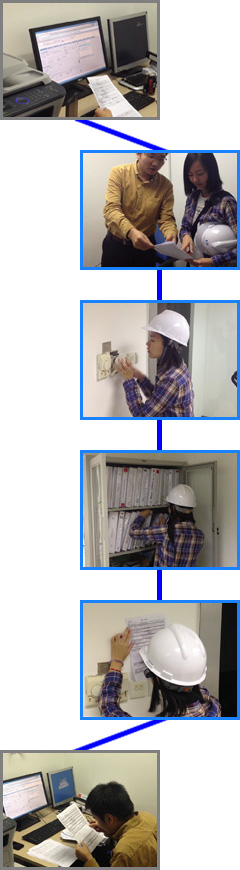

Printing work orders from the CMMS is a highly inefficient process, even when the CMMS is working well (which is seldom the case, some companies cut and paste into Word files….).

Paper work orders must then be handed over to the technician. The information printed is often incomplete, leaving the technician to look for additional documents before going for the job.

Only after having received the paper work order at the office, can the technician go to site. The need to obtain paper instructions may increase the amount of time spent traveling.

To make a diagnosis or to identify the necessary parts, technician may need to come back to the office to consult drawings or manuals that may be out of date or not easily accessible.

Having to write feedback on paper is a low-value administrative activity often despised (and misunderstood) by technicians, resulting in inaccurate information.

Handwritten forms are often inaccurate, illegible and do not match CMMS requirements. The most tedious part of the process is for the unlucky “CMMS secretary” to input data in the computer.

With bluebee®, all administrative aspects of the work order process disappear and information is readily available, in the field:

Technician is notified of new work orders while already in the field, thus reducing travel time. History, past diagnosis, relevant documents etc. are all accessible in bluebee®.

Feedback is intuitive, based on checklists, scanning, photos; time and GPS coordinates are captured automatically; the CMMS database is immediately updated without human intervention.

Direct payback

Payback from time saving can easily be computed by multiplying the time saved by the burdened labor rate (full wage plus overhead costs).

Time is freed to focus on preventive maintenance

It is almost impossible for technical teams tied-up handling emergencies, operating in constant firefighting mode, as is often the case in China, to launch a preventive maintenance program. On the other hand, few companies will afford the necessary additional resources. This simple fact is the number one obstacle in maintenance improvement projects.

Time freed by using bluebee® in the work order process can be immediately allocated to improvement actions and preventive maintenance, thus enabling the real benefits – the bottom of the iceberg.