Stable Operations: How a Leading Hazardous Waste Treatment Company Uses Smart Technology to Navigate Industry Downturns

About Sino-Singapore SUEZ

Sino-Singapore SUEZ is the implementing entity for the comprehensive solid waste disposal project in Suzhou Industrial Park. The company is dedicated to providing long-term, safe, and reliable solid waste treatment services to clients in Suzhou and its surrounding areas, serving over 500 clients. The project has a total investment of approximately 360 million yuan, with an annual disposal capacity of 30,000 tons. It can incinerate hazardous waste across 23 categories, recycle 70,000 tons of steam annually, and reduce greenhouse gas emissions by about 13,000 tons of CO2 equivalent, promoting a circular economy and energy conservation. The project’s emission standards adhere to the strictest European Union 2010 regulations.

Project milestones and benefits

Construction of the plant began in 2018 and the project reached mechanical completion by August 2019. In September of the same year, leveraging best operational practices from SUEZ Group and Siveco China’s ISO 55000-based maintenance management methodology, the plant successfully launched the Smart Operations and Maintenance (O&M) system, based on Coswin 8i. The system ensured effective support for the plant’s commissioning and commercial operations.

During the first phase of the project, the following goals were achieved:

- Definition of a comprehensive maintenance management strategy with clear, traceable management metrics.

- Delivery of a detailed equipment list to the operations team, including comprehensive equipment information, defined equipment criticality, clear equipment structure, and spare parts lists.

- Work management ensuring all equipment faults are accurately recorded in the system according to defined forms.

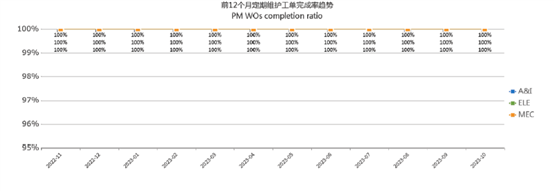

- Establishment of a preventive maintenance management system, including clear work content and plans.

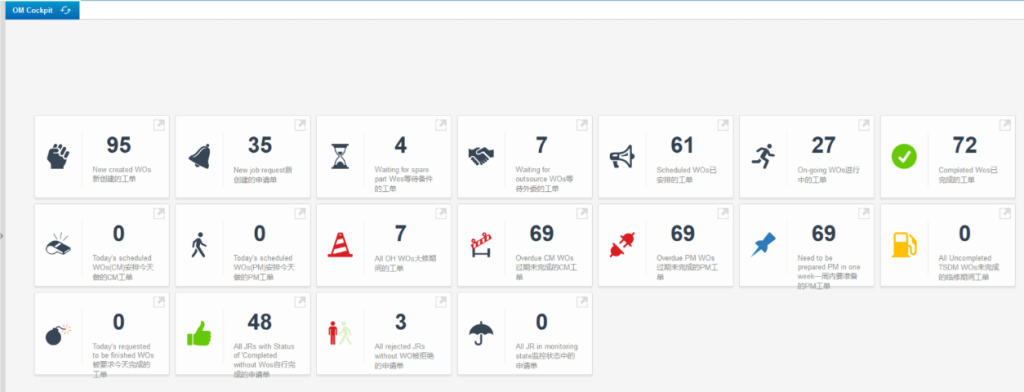

- Provision of a dashboard for management to track maintenance progress.

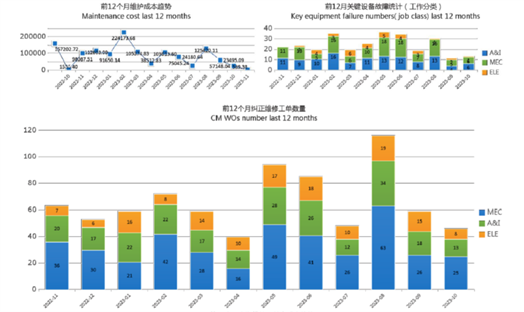

- Development of a reporting system to facilitate continuous improvement analysis.

In April 2020, Sino-Singapore SUEZ incorporated the factory’s inventory and procurement management into the CMMS system, achieving the full digitalization of the factory’s daily operation management. Particularly, the cost management in the maintenance management process has achieved a closed-loop, making it possible to analyze the maintenance cost of each piece of equipment or process unit, providing insights into the use of maintenance budgets under the current maintenance policy.

Subsequently, by leveraging Phase Two of the project, the following goals were achieved:

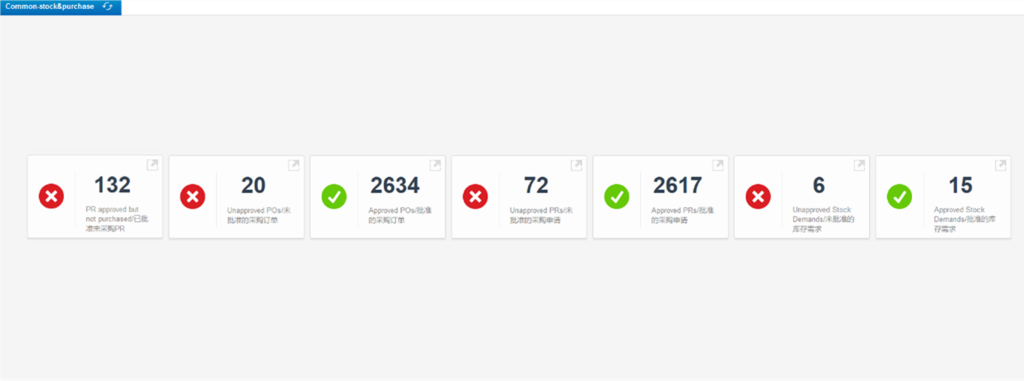

- Streamlining and optimizing inventory and procurement processes, thereby bringing direct improvements.

- Comprehensive inventory management, including parts and consumables, linking them with equipment and work orders. The system provides quick access to inventory quantities, locations, suppliers, and unit prices, as well as demand forecasting and technical requirements for procurement based on preventive maintenance plans and historical consumption.

- Establishment of a procurement management process from Purchase Requisition (PR) to Purchase Order (PO), including supplier management, account period management, and outsourced service procurement.

Sustainable Improvement

As a customer of Siveco China Enhanced Maintenance Support, after the project went live, in addition to regular software and network support, Sino-Singapore SUEZ benefits from an on-site assessment of the system usage every year.

These assessments combine the management needs of Sino-Singapore SUEZ, resulting in clear improvement measures and ensuring that the customer can gradually improve system usage on a yearly basis, to meet maintenance goals, which will be mutually agreed and measurable.

On January 30, 2024, Sino-Singapore SUEZ was awarded the 2023 ESG Award by SUEZ Asia, among 12 companies recognized across five major categories. Sino-Singapore SUEZ’s “Waste Liquid Canning Workshop Safety and Environment Comprehensive Improvement Project” won the “Occupational Safety and Health Category-Most Effective Risk Control Plan”, which demonstrated the company’s continuous actions and innovative measures in safety and environmental risk control. In view of the high safety risk coefficient of canning operations, the company has adopted an overall risk prevention and control plan to reduce safety risks in the work area and control the occurrence of production accidents.

General Manager Chen Miao commented on the long-term cooperation with Siveco China: “Digital transformation and the application of new technologies are the future trends the plant is embracing. Sino-Singapore SUEZ looks forward to explore more possibilities with Siveco China for innovation in operation and maintenance management. “

Siveco China’s Managing Director Bruno Lhopiteau replied: “We are pleased to hear that our solution have played a crucial role in supporting the plant’s daily operation and regulatory compliance. Considering Sino-Singapore SUEZ’s comprehensive project scope (maintenance, inventory, and procurement), our solutions have created greater transparency for decision support.”

For four consecutive years, Sino-Singapore SUEZ has won the “Excellent Case” Award for Corporate Social Responsibility Construction in Suzhou Industrial Park. In the face of the overall operational pressure of the hazardous waste industry, thanks to SUEZ’s advanced operational management concept, Sino-Singapore SUEZ conducted a detailed analysis of maintenance costs and identified improvement areas, initially reducing maintenance costs. With an excellent maintenance management system in place, the plant ensures stable and efficient operations. The company continues to enhance its internal and external capabilities, addressing challenges, maintaining production stability, and promoting innovation to achieve higher standards in its comprehensive operational capabilities, providing customers with safe, reliable, stable, and high-quality hazardous waste disposal services.